Compact Laser Diode Modules

- Max Power Ranging from 4.0 to 20 mW

- Six Versions with Wavelengths Ranging from 405 to 1550 nm

- SM1-Threaded for Lens Tube Compatibility

Front

LDM785

785 nm, 20 mW

LDM785

Shown in

a KM200V

Rear

Please Wait

| Item # | Wavelength (Typical) |

Beam Size (Elliptical) |

Output Power |

Class |

|---|---|---|---|---|

| LDM405 | 405 nm | 3.0 mm x 5.0 mm | 4.0 mW | 3R |

| LDM635 | 635 nm | 3.0 mm x 5.0 mm | 4.0 mW | 3R |

| LDM670 | 670 nm | 2.2 mm x 4.4 mm | 5.5 mW | 3B |

| LDM785 | 785 nm | 2.6 mm x 4.4 mm | 20 mW | 3B |

| LDM850 | 850 nm | 3.5 mm x 4.4 mm | 20 mW | 3B |

| LDM1550 | 1550 nm | 2.6 mm x 3.0 mm | 4.5 mW | 1 |

Features

- Adjustable Output Power

- Collimated Output Beam

- Integrated Beam Shutter

- Internal SM1 (1.035"-40) Threads

- IEC60825-1/CDRH Compliant

- Power Supply Included

The LDM Series of compact laser sources are well suited to benchtop optical experiments. They are available at six wavelengths: 405 nm, 635 nm, 670 nm, 785 nm, 850 nm, and 1550 nm.

The Ø1.40" by 5.8" housing contains a Fabry-Perot laser diode with a bandwidth typically around 1 nm, collimating lens, and power controller. Each laser diode module includes a built-in shutter and internal SM1 (1.035"-40) threads for mounting with an extensive range of optomechanical devices from lens tubes to lens mounts. These laser modules are typically used as alignment aids within an SM1 Lens Tube system, as shown in Figure 1.1.

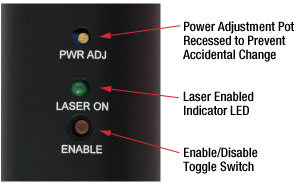

The LDM modules can be mounted to any optical table using one of our C1512(/M), C1513(/M), KM200V(/M), or VC3C(/M) V-groove mounts. Besides the mechanical shutter, the module also features a remote interlock connection and key-lock power switch. The laser module has an enable/disable toggle switch, laser on indicator LED, and top-located power adjustment pot controller.

The power can be adjusted from 0 to full power by adjusting a pot, as shown in Figure 1.2. The output of each laser diode is polarized and multi-longitudinal mode. When the Laser Enable button is facing up, the light will be vertically polarized, with the exception of the LDM635, which will have horizontal polarization. Each LDM comes with a universal power supply.

Figure 1.3 Key-Lock, Power Port, and Interlock with Shorting Pin

Figure 1.2 LDM Series Top Controls

Click to Enlarge

Figure 1.1 LDM785 Laser Diode Module Shown Mounted on a Ø1.5" Post Using a Kinematic

| Item # | LDM405 | LDM635 | LDM670 | LDM785 | LDM850 | LDM1550 |

|---|---|---|---|---|---|---|

| Wavelength, Typical | 405 nm | 635 nm | 670 nm | 785 nm | 850 nm | 1550 nm |

| Wavelength, Min/Max | 395 - 415 nm | 625 - 645 nm | 660 - 678 nm | 776 - 800 nm | 840 - 860 nm | 1520 - 1580 nm |

| Beam Size (Elliptical)a | 3.0 mm x 5.0 mm | 3.0 mm x 5.0 mm | 2.2 mm x 4.4 mm | 2.6 mm x 4.4 mm | 3.5 mm x 4.4 mm | 2.6 mm x 3.0 mm |

| Output Powerb | 4.0 mW | 4.0 mW | 5.5 mW | 20 mW | 20 mW | 4.5 mW |

| Common Specifications | |

|---|---|

| Stability, Short Term (30 min) | 0.01 dB |

| Stability, Long-Term Drift (24 hr) | 0.1 dB |

| Operating Temperature | 10 - 40 °C |

| Storage Temperature | 5 - 50 °C |

| Power Supply (Included) | Input: 100 - 240 VAC, 0.48 A 50 - 60 Hz Output: 9 VDC @ 2.2 A |

Laser Safety and Classification

Safe practices and proper usage of safety equipment should be taken into consideration when operating lasers. The eye is susceptible to injury, even from very low levels of laser light. Thorlabs offers a range of laser safety accessories that can be used to reduce the risk of accidents or injuries. Laser emission in the visible and near infrared spectral ranges has the greatest potential for retinal injury, as the cornea and lens are transparent to those wavelengths, and the lens can focus the laser energy onto the retina.

Safe Practices and Light Safety Accessories

- Laser safety eyewear must be worn whenever working with Class 3 or 4 lasers.

- Regardless of laser class, Thorlabs recommends the use of laser safety eyewear whenever working with laser beams with non-negligible powers, since metallic tools such as screwdrivers can accidentally redirect a beam.

- Laser goggles designed for specific wavelengths should be clearly available near laser setups to protect the wearer from unintentional laser reflections.

- Goggles are marked with the wavelength range over which protection is afforded and the minimum optical density within that range.

- Laser Safety Curtains and Laser Safety Fabric shield other parts of the lab from high energy lasers.

- Blackout Materials can prevent direct or reflected light from leaving the experimental setup area.

- Thorlabs' Enclosure Systems can be used to contain optical setups to isolate or minimize laser hazards.

- A fiber-pigtailed laser should always be turned off before connecting it to or disconnecting it from another fiber, especially when the laser is at power levels above 10 mW.

- All beams should be terminated at the edge of the table, and laboratory doors should be closed whenever a laser is in use.

- Do not place laser beams at eye level.

- Carry out experiments on an optical table such that all laser beams travel horizontally.

- Remove unnecessary reflective items such as reflective jewelry (e.g., rings, watches, etc.) while working near the beam path.

- Be aware that lenses and other optical devices may reflect a portion of the incident beam from the front or rear surface.

- Operate a laser at the minimum power necessary for any operation.

- If possible, reduce the output power of a laser during alignment procedures.

- Use beam shutters and filters to reduce the beam power.

- Post appropriate warning signs or labels near laser setups or rooms.

- Use a laser sign with a lightbox if operating Class 3R or 4 lasers (i.e., lasers requiring the use of a safety interlock).

- Do not use Laser Viewing Cards in place of a proper Beam Trap.

Laser Classification

Lasers are categorized into different classes according to their ability to cause eye and other damage. The International Electrotechnical Commission (IEC) is a global organization that prepares and publishes international standards for all electrical, electronic, and related technologies. The IEC document 60825-1 outlines the safety of laser products. A description of each class of laser is given below:

| Class | Description | Warning Label |

|---|---|---|

| 1 | This class of laser is safe under all conditions of normal use, including use with optical instruments for intrabeam viewing. Lasers in this class do not emit radiation at levels that may cause injury during normal operation, and therefore the maximum permissible exposure (MPE) cannot be exceeded. Class 1 lasers can also include enclosed, high-power lasers where exposure to the radiation is not possible without opening or shutting down the laser. |  |

| 1M | Class 1M lasers are safe except when used in conjunction with optical components such as telescopes and microscopes. Lasers belonging to this class emit large-diameter or divergent beams, and the MPE cannot normally be exceeded unless focusing or imaging optics are used to narrow the beam. However, if the beam is refocused, the hazard may be increased and the class may be changed accordingly. |  |

| 2 | Class 2 lasers, which are limited to 1 mW of visible continuous-wave radiation, are safe because the blink reflex will limit the exposure in the eye to 0.25 seconds. This category only applies to visible radiation (400 - 700 nm). |  |

| 2M | Because of the blink reflex, this class of laser is classified as safe as long as the beam is not viewed through optical instruments. This laser class also applies to larger-diameter or diverging laser beams. |  |

| 3R | Class 3R lasers produce visible and invisible light that is hazardous under direct and specular-reflection viewing conditions. Eye injuries may occur if you directly view the beam, especially when using optical instruments. Lasers in this class are considered safe as long as they are handled with restricted beam viewing. The MPE can be exceeded with this class of laser; however, this presents a low risk level to injury. Visible, continuous-wave lasers in this class are limited to 5 mW of output power. |  |

| 3B | Class 3B lasers are hazardous to the eye if exposed directly. Diffuse reflections are usually not harmful, but may be when using higher-power Class 3B lasers. Safe handling of devices in this class includes wearing protective eyewear where direct viewing of the laser beam may occur. Lasers of this class must be equipped with a key switch and a safety interlock; moreover, laser safety signs should be used, such that the laser cannot be used without the safety light turning on. Laser products with power output near the upper range of Class 3B may also cause skin burns. |  |

| 4 | This class of laser may cause damage to the skin, and also to the eye, even from the viewing of diffuse reflections. These hazards may also apply to indirect or non-specular reflections of the beam, even from apparently matte surfaces. Great care must be taken when handling these lasers. They also represent a fire risk, because they may ignite combustible material. Class 4 lasers must be equipped with a key switch and a safety interlock. |  |

| All class 2 lasers (and higher) must display, in addition to the corresponding sign above, this triangular warning sign. |  |

|

Click to Enlarge

Figure 4.1 LDM635 Packaging

| Item # | % Weight Reduction |

CO2-Equivalent Reductiona |

|---|---|---|

| LDM405 | 9.63% | 0.4 kg |

| LDM635 | 9.63% | 0.87 kg |

| LDM670 | 9.63% | 0.49 kg |

| LDM785 | 9.63% | 0.54 kg |

| LDM850 | 9.63% | 0.43 kg |

| LDM1550 | 9.63% | 0.62 kg |

Smart Pack

- Reduce Weight of Packaging Materials

- Increase Usage of Recyclable Packing Materials

- Improve Packing Integrity

- Decrease Shipping Costs

Thorlabs' Smart Pack Initiative is aimed at waste minimization while still maintaining adequate protection for our products. By eliminating any unnecessary packaging, implementing packaging design changes, and utilizing eco-friendly packaging materials for our customers when possible, this initiative seeks to improve the environmental impact of our product packaging. Products listed here are now shipped in re-engineered packaging that minimizes the weight and the use of non-recyclable materials.b

| Posted Comments: | |

user

(posted 2024-02-09 15:47:16.96) How would one mount a LDM405 laser inside a cage system directly? Is it possible with off-the-shelf parts from Thorlabs, or do we have to custom machine some parts? ksosnowski

(posted 2024-02-09 12:04:19.0) Thanks for reaching out to Thorlabs. LDM405 and the LDMxxx series of laser modules have internal SM1 threading at the output aperture which is 0.15 inches deep. Using an externally threaded lens tube coupler like SM1T2, which is 0.5 inches long, you can connect the laser to the SM1 threads in the cageplate CP33 which are 0.35" deep. The outer diameter of the LDM405 is 1.40 inches as shown on our 2D CAD file. We do not have any adapters for this specific size to raise the diameter to 2 inches for use in the larger 60mm cageplate like LCP34. There are other adapters to step between 30mm to 60mm cage sizes if needed however. Ana Aguayo

(posted 2023-01-30 17:41:13.953) Hi! In my lab we bought a LDM785 laser and the laser spot is pretty ugly, resembles an interference pattern and I couldn't clean it even with a monomodal fiber, because I get a circular interference pattern no matters what fiber I use. I would like to know if you have some suggestions to improve the spot. Thannk you. ksosnowski

(posted 2023-02-09 11:56:18.0) Hello Ana, thanks for reaching out to Thorlabs. It sounds like the fiber is not behaving as single mode in this setup. This could be due to the choice of fiber or launch conditions. I have reached out directly to discuss your application further. Abhay Anand

(posted 2022-06-24 13:52:07.6) We are planning to order LDM 635. How long it will take to deliver this product ? Availability status showing lead time. ksosnowski

(posted 2022-06-24 09:43:32.0) Thanks for reaching out to Thorlabs. Please direct any further lead time/availability questions to sales@thorlabs.com for the most prompt response. Martin COOPER

(posted 2022-02-25 11:53:28.53) I have a LDM1550 and if you had 1064 nm and 1319 nm versions I would have bought them...

Cheers ksosnowski

(posted 2022-02-25 07:04:32.0) Thanks for reaching out to Thorlabs. While we currently do not have any compact modules like LDM1550 for 1064nm or 1319nm, depending on your spectral and power requirements you may consider our Benchtop Fiber-coupled Lasers for turnkey operation. For more narrow spectra it may require a diode and driver. I have reached out directly to discuss your application further. user

(posted 2022-01-05 14:26:21.373) Hi, is there any idea of the response and rise time of the shutter? cdolbashian

(posted 2022-01-05 04:08:40.0) Thank you for reaching out to us at Thorlabs. The shutter is a manual mechanical shutter, and as such does not have an associated rise time. Damini Frey

(posted 2021-11-01 14:07:02.277) Is it possible to purchase the 9 V, 2.2 A power supply separately? cdolbashian

(posted 2021-11-04 04:13:07.0) Thank you for reaching out to us at Thorlabs. For requests such as this, please contact techsupport@thorlabs.com in the future. I have reached out to you directly to discuss the pricing of this particular power supply. akuznetsov

(posted 2018-12-10 15:20:50.053) What is the light output stability of these lasers in percent?

Would like to see 523nm and 940nm versions of these lasers!

What is the beam divergence? YLohia

(posted 2019-01-02 09:15:21.0) Hello, thank you for contacting Thorlabs. We specify the stability in dB in the spec sheets of these lasers, with short term stability being 0.01 dB (0.230%) and long term being 0.1 dB (2.329%).

Currently, these lasers are collimated by checking to make sure that the beam size stays the same over a distance of about 3m. We realize this is not a very exact process and are looking to change it in the future, but for now this is the procedure so we do not have a definitive spec for divergence. Over 3m, it's typical to see around 0.08 - 0.60 mrad divergence.

I have posted a suggestion for these two wavelengths on our internal engineering forum for further consideration. yur-yulya

(posted 2017-11-23 10:11:45.257) Does the package contain adapters for the power supply presented on the product picture? nbayconich

(posted 2017-12-28 02:45:17.0) Thank you for contacting Thorlabs. The entire adapter set is not provided in the product picture of the LDM635. The appropriate adapter will be shipped depending on your location.

If you would like the additional power supply adapters or power supplies please contact us at techsupport to request these as special order items. I will reach out to you directly with more information. wenzel.jakob

(posted 2017-10-14 23:39:25.96) I'm interested in the degree of polarization of these laser diodes. Apart from the shutter & interlock, what are the main differences to the lower-priced CPS family of laser diode modules? nbayconich

(posted 2017-10-19 10:51:58.0) Thank you for contacting Thorlabs. The LDM series laser diodes typically have a TE linear polarization, and have a typical PER of 20-30 dB. The LDM series have an adjustable output power and are offered with a higher output power and a longer available wavelength range than the CPS diodes. The CPS laser diodes are more for a simple plug and play option and do not have the ability to adjust the output. leonlopez

(posted 2015-07-27 00:12:13.447) hi i am Leonardo Lopez a physical engineer from Colombia and I would like that you could send me a quote of the product #LDM670 with all expenses would have , it is a requirement that I need to buy through my university resources, thanks. jlow

(posted 2015-08-25 03:15:14.0) Response from Jeremy at Thorlabs: We will contact you directly for a quote. You can contact us directly at sales@thorlabs.com to request a quote as well. thomas.liebig

(posted 2015-06-24 14:46:56.26) Is there any specification on M² or divergence available. Otherwise it is also rather difficult to estimate power loss when cleaning up the profile. besembeson

(posted 2015-08-19 08:59:40.0) Response from Bweh at Thorlabs USA: The typical value for the mean M^2 is 1.66. user

(posted 2015-06-22 16:17:09.25) In specification tub, beam size and max power is well specified. But are they typical values or what you can offer? I am happy if I can have 3.0mm x 5.0mm size without any tolerances for all I would buy. besembeson

(posted 2015-09-21 02:35:22.0) Response from Bweh at Thorlabs USA: These are typical values that you should expect for each corresponding unit. Note that for the beam diameter, this is measured 3mm from the module. florian.schuelein

(posted 2014-10-16 14:11:31.343) Hi everybody,

Is there an option with green laser diodes?

Best regards

Florian Schülein jlow

(posted 2014-10-22 03:08:09.0) Response from Jeremy at Thorlabs: We do not currently have the green laser in the LDM modules. We do have other green laser diode modules available such as the CPS532 and CPS532-C2. You can find them at http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=1487 thorben.jostmeier

(posted 2014-08-22 10:02:34.343) Regarding the polarization state (of the LDM1550), I can confirm what rice posted: the electric field polarization state is NOT HORIZONTAL when the enable button is facing up, but almost vertical. We checked this using a pre-aligned LPNIR polarizer. jlow

(posted 2015-01-12 04:08:46.0) Response from Jeremy at Thorlabs: We have updated the web presentation to reflect the correct polarization direction of our laser diode modules. stockbr

(posted 2014-08-05 09:56:04.657) What is the bandwidth of these lasers? I do not see this spec listed anywhere. jlow

(posted 2014-08-06 08:36:45.0) Response from Jeremy at Thorlabs: These laser diodes used in these modules are regular Fabry-Perot laser diode and typically have linewidth around 1nm or so. h.rutt

(posted 2014-06-17 17:31:30.547) This series has an 'enable' button.

There needs to be provision to enable *remotely*; sometimes it is not accessible, and its also not good for alignment.

The lack of one is a big problem for us right now. Obviously it would invalidate warranties etc, but would it be practical to open it up (the screws at the back presumably) & add a parallel connection across the push button to provide remote enable?

(Holding it down doesnt work :-( ) jlow

(posted 2014-07-29 04:05:31.0) Response from Jeremy at Thorlabs: Thank you for your feedback. We will look into the possibility of adding this in the future. With regard to modification, it is possible to do something like that but that will definitely void the warranty. I will contact you to provide some detail on the switch. rice

(posted 2014-06-09 14:03:57.85) Polarization state of the LDM405 laser module: the output appears to be polarized with the E-FIELD VERTICAL when the output enable button is facing up. I confirmed this by using reflection from a glass plate to observe the Brewster angle as well as by passing the beam through your LPVISE 100-A linear polarizer, which passes the beam when its polarization mark (red dot) is aligned VERTICALLY when the LDM405 is mounted with its controls facing up. hillbill2

(posted 2014-03-24 13:39:47.363) Is there a device to couple a PAF-SMA-11-B to the front of the LDM laser diode laser tube? (You have this capability for a HeNe laser) cdaly

(posted 2014-03-25 12:26:29.0) Response from Chris at Thorlabs: There isn't a specific part dedicated for this purpose, but you could use an SM1T2 lens tube coupler with a CP08FP fiber port mounting cage plate in order to mate the two together. Both the LDM laser modules and this plate have internal SM1 threading which would thread onto the externally SM1-threaded coupler. user

(posted 2013-11-15 17:57:59.553) Are the LDM series laser single longitudinal mode or multimode? thanks, j jlow

(posted 2013-11-18 08:24:17.0) Response from Jeremy at Thorlabs: The LDM series laser are multi-longitudunal mode. user

(posted 2013-07-18 11:25:14.03) Im looking for the M2 parameter for LDM1550. Is it similar to the M2 for LDM635 that I found here? pbui

(posted 2013-08-07 16:23:00.0) Response from Phong at Thorlabs: We do not test the LDM1550's M2 parameter since it is not optimized for this. If you're looking to achieve a good M2 value, we would suggest coupling the laser's output to a single mode fiber to clean up the profile to make it more Gaussian. bdada

(posted 2011-11-17 17:55:00.0) Response from Buki at Thorlabs:

Thank you for your feedback. Unfortunately the only way to implement a remote enable function is just how you described, by running a pair of wires in parallel with the internal tact switch. If you prefer that we do it, please contact TechSupport@thorlabs.com to request a quote.

Please note that the enable circuit requires a momentary closure to enable and disable the laser. You can leave the switch closed as long as you wish, but you need to return it to an open state and then close it again in order to toggle the state of the unit. martinisabelle30

(posted 2011-11-02 15:12:53.0) Hello, I purchased one of your LDM635 and LDM405 laser modules, and I need to mount it inside an enclosure and control it remotely. I understand from a previous post that they have already tried using the "Interlock" connection, but even with that switch contact closed, the "enable" button must still be pressed manually to turn the laser on.

Is there anyway that this laser can be controlled remotely or without using this toggle switch? Like the user before mentioned, I might have to resort to disassemble the laser and bring the "enable" switch contacts out on a pair of wires to a second control relay. This I would prefer not doing in case of damaging the laser components. Martin bdada

(posted 2011-08-25 12:46:00.0) Response from Buki at Thorlabs:

Thank you for your feedback. Currently, we list SM1 compatibility as one of the features listed for the LDM laser modules on the web page. We also discuss it in the overview section.

http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=1219&pn=LDM635#1219

Based on your feedback, we will review the web page to see how we can better highlight the SM1 compatibility of the LDM laser modules. v-clydew

(posted 2011-08-25 07:37:02.0) In my opinion, the most important feature of this type of laser module (LDM635, etc.) is the fact that it has 1" diameter lenstube thread on the end. I would never have known this if I had not gone into the "drawings" and looked for it specifically. This feature will sell this laser to anyone who uses Thor lenstubes and yet it is not promoted on the front page. You are missing out on sales by not pushing the lenstube feature of this alignment laser. Everyone who uses lenstubes will have a use for an alignment beam (battery driven!) that simply screws onto existing fixtures. Wake up! Thorlabs

(posted 2010-07-28 17:36:43.0) Response from Javier at Thorlabs to last poster: Thank you for your feedback. The polarization of the laser is parallel to your optical table when the Laser Enable button is facing up. user

(posted 2010-07-25 17:35:04.0) Hi, what is the polarization state of the LDM405 laser?. Thanks in advanced. jens

(posted 2009-06-18 18:40:20.0) A reply from Jens at Thorlabs: the lens position can not be adjusted in this model. In order to change the beam characteristics external optics will be required. john

(posted 2009-06-16 20:52:14.0) Is it possible for the user to adjust the collimation lens so that the output is diverging or converging? mwalker

(posted 2009-04-17 12:58:29.0) Hello, I purchased one of your LDM635 laser modules, and I need to mount it inside an enclosure and control it remotely. I have already tried using the "Interlock" connection, but even with that switch contact closed, the "enable" button must be pressed manually to turn the laser on. Is there any way around this? If not, Im afraid Ill have to disassemble the laser and bring the "enable" switch contacts out on a pair of wires to a second control relay. Thanks for your help. -Mark Tyler

(posted 2008-04-14 15:16:20.0) A response from Tyler at Thorlabs: The M^2 parameters for the LDM635 are as follows: x-direction: 1,094 and y-direction: 1,058 for an average value of 1,076. These values are nominal. Tyler

(posted 2008-04-07 09:34:58.0) A response from Tyler at Thorlabs to adelon: Thank you for your interest in our laser module. Your request has been forwarded to our technical support department. They will soon be in contact with you via email. adelon

(posted 2008-04-01 05:42:58.0) Dear sir, madam,

Could you provide us more precise information about the spatial properties of the laser module LDM635 ?

What are the M2 parameters along each direction of the elliptical output beam ?

Sincerely yours, A.Delon technicalmarketing

(posted 2007-08-22 09:09:10.0) Thank you for your interest in the LDM405. The power stability specifications are list under the "Specs" tab and the module does come with a power supply. For a dialog about this product please consider contacting our technical support staff. onnes79

(posted 2007-08-22 04:52:37.0) I'm interested in the model LDM405.

Is there any information about power stability?

I want to know the fluctuation of power from mean power.

And does this LD module contain power-supply unit or should I buy that unit? |

Products Home

Products Home

LD Modules with Shutter

LD Modules with Shutter