Breadboard Feet and Seats

- Help Stabilize Your Breadboards

- Useful for Uneven Surfaces

- Reduce Shock

SWB

Articulated Stainless

Steel Mounting Foot

AV4

Vibration Absorbing Feet

(Pack of 4)

BMF4

Breadboard Feet

(Pack of 4)

KBS98

Kinematic Breadboard Seats

DF1

Low Friction

Breadboard Feet

(Pack of 3)

Top Plates

Bottom Plates

±6°

±10°

Please Wait

Features

- Rubber Damping Feet

- Adjustable Breadboard Feet

- Articulated Stainless Steel Mounting Feet

- Slidable Breadboard Feet

- Kinematic Breadboard Seats

- Vibration Isolating Sorbothane Feet

The range of feet offered here can be used to stabilize various breadboards. Please see below for more details.

Selecting the Proper Sorbothane Isolator Feet

The example presented here details the steps needed to ensure the proper selection of round sorbothane isolator feet to match the requirements of a particular load and problem frequency. Following the example are plots showing the amount of isolation achieved for our isolator feet. For specific isolation recommendations, please contact Tech Support.

Example

- Mass of the Breadboard (mb): 44 lbs

- Mass of Mounted Optics, Posts, Hardware, and Stages (me): 10 lbs

- Number of Isolators (n): 4

- Problem Frequency: Unknown

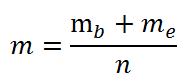

The round sorbothane feet's isolation graphs, shown in Figures 2.1, 2.2, 2.3, and 2.4, use load per isolator (m) in lbs, which is given by the following equation:

Based on the values given above, the calculated load per isolator is 13.5 lbs. This value should then be looked up on each isolation graph for the round isolator feet below. Sorbothane feet with a calculated load per isolator that exceeds the maximum load are not suitable for the application. Without a known problem frequency, the isolator that effectively isolates at the lowest cut-on frequency is recommended.

For this example, the AV4(/M) or AV5(/M) sorbothane feet would both be acceptable solutions. The AV4 Ø27 mm isolator feet provide better isolation performance at lower frequencies but are near the load limit, so if the total load were higher than anticipated the isolator would be outside of the recommended load capacity. Our AV5 Ø38.1 mm isolator feet will have worse isolation performance at lower frequencies, but are well within the load range which may be preferable.

If a sorbothane sheet is preferred, it would need to be cut to an appropriate size as described in the full web presentation on Sorbothane Isolators. For a 13.5 lb (6.1 kg) load, a 0.5" (12.7 mm) thick sheet cut into 1.5" x 0.5" (38.1 mm x 12.7 mm) pieces would provide a good isolation solution.

Sorbothane Feet Isolation Plots

Click to Enlarge

Figure 2.1 The plot shown above shows the isolation efficiency per foot of the AV3 Sorbothane Isolator Feet. These isolators should not be used above the maximum load capacity of 6 lbs. Above this weight, the isolators will begin to amplify vibrations rather than damp them.

Click to Enlarge

Figure 2.2 The plot shown above shows the isolation efficiency per foot of the AV4(/M) Sorbothane Isolator Feet. These isolators should not be used above the maximum load capacity of 14 lbs. Above this weight, the isolators will begin to amplify vibrations rather than damp them.

Click to Enlarge

Figure 2.3 The plot shown above shows the isolation efficiency per foot of the AV5(/M) Sorbothane Isolator Feet. These isolators should not be used above the maximum load capacity of 33 lbs. Above this weight, the isolators will begin to amplify vibrations rather than damp them.

Click to Enlarge

Figure 2.4 The plot shown above shows the isolation efficiency per foot of the AV6(/M) Sorbothane Isolator Feet. These isolators should not be used above the maximum load capacity of 50 lbs. Above this weight, the isolators will begin to amplify vibrations rather than damp them.

| Posted Comments: | |

user

(posted 2023-09-29 08:29:52.6) how I can compare vibration properties of BMF4/M and AV serie? I see plots for AV but not for BMF4/M cdolbashian

(posted 2023-10-19 09:14:09.0) Thank you for reaching out to us with this inquiry. They are not really comparable products though they live on the same page. The AV-line of isolators are made from sorbothane, which is known to be a passive isolation/damping material. On the other hand the BMF4 is not made from such a material, and simply provides rubberized feet for minor damping functionality, with the added feature of levelling and the ability to be stable on a non-flat surface, due to the 10° pivoting capabilities. If you have additional inquiries, please reach out to us via email at Techsupport@thorlabs.com. |

Click for Details

Figure G1.3 An MB810U Breadboard Supported by Ø1" Posts Fitted With RDF1 Rubber Damping Feet

Click to Enlarge

Figure G1.2 An MB810U Breadboard Supported by BMF4 Mounting Feet that are Attached Using the Included Cap Screws

- Accepts 1/4"-20 (or M6) Socket Head Cap Screws (Included Only with BMF4)

- Helps Reduce Shock and Vibration

- Useful for Uneven Surfaces

The RDF1 Rubber Damping Feet are useful for stabilizing aluminum breadboards. Mount one foot under each corner of the breadboard to help reduce vibrations and to compensate for uneven work surfaces. The Ø1" feet help support heavy loads and accept either the imperial (1/4") or metric (M6) socket head cap screws found in our HW-KIT2 and HW-KIT2/M hardware kits, respectively.

The BMF4 Adjustable Breadboard Feet can be used to stabilize any of our aluminum or stainless steel breadboards. One foot is mounted under each corner to help reduce vibration. They provide ±0.120" (±3 mm) of vertical height adjustment to allow the breadboard to be leveled using a novel ±10° pivot design that compensates for uneven work surfaces. The BMF4 comes with 1/4"-20 socket head cap screws, while the BMF4/M comes with M6 socket head cap screws.

Click for Details

Figure 595C Mounting Base Being Used to Level and Secure an Optical Breadboard

Click to Enlarge

Figure 595B SWB Mounting Base with Locking Nut Removed

Click for Details

Figure 595A Cross Sectional View of the SWB(/M) Base

- 0.66" Long, 1/4"-20 (M6) Threaded Mounting Stud

- CF125 or CF175 Clamping Fork (Sold Separately) Secures Base and Locks Swivel Joint

- ±6° Swivel Compensates for Uneven Surfaces

- Locking Nut Included for Height Adjustments

- 1/8" (3 mm) Hex Socket on Bottom for Tightening

- Machined Bottom Relief Cut for Added Stability

Thorlabs' SWB(/M) Ø1.25" (31.8 mm) Articulated Mounting Base can be used to stabilize and level a mounted component, such as a breadboard, or to correct for beam pointing errors. It features a 0.66" long, 1/4"-20 (M6) threaded mounting stud with ±6° of freedom in all directions to adjust for uneven work surfaces or compensate for angular misalignment. The base can be secured to an optical table or breadboard using a clamping fork, such as the CF125 or CF175, as shown in Figure 595C. Securing the base in place with a clamping fork will lock the articulated joint in position.

A Ø1" tapered locking nut is included for components requiring a larger support surface and provides 0.375" of vertical height adjustment. The tapered design prevents the locking nut from contacting a clamping fork when being secured in place. Additionally, torque holes that accept a 5/64" hex key are included in the lock nut and mounting stud to aid in securing a mounted component at a specific height. A 1/8" (3 mm) hex socket is also included on the bottom of the mounting base to actuate the threaded mounting stud.

Click to Enlarge

Figure G3.2 DF1 Feet Mounted to an MB8 Breadboard

Click to Enlarge

Figure G3.1 Breadboard (MB8) with low-friction feet. KL01 kinematic stops preserve breadboard location.

- Low-Friction Delrin®*

- Allow Breadboards to be Moved Easily

- 1/4"-20 or M6 Mounting Studs

- Helps Reduce Shock and Vibration

The DF1 Feet are useful for smaller aluminum breadboards in applications that require frequent repositioning. Made from low-friction Delrin, they allow the breadboard to slide easily without marking or scratching the work surface. Supplied as a set of three, the feet have a simple 1/4"-20 or M6 stud and are ideal for use with our range of kinematic breadboard stops.

Figure G3.1 shows three KL01 Kinematic Stops being used to maintain the position of an MB8 Breadboard with DF1 Low-Friction Feet. To match the height of the breadboard and low-friction feet, each KL01 stop is mounted on a BA2S6 Spacer. Two KL01 stops are used to define a line on one edge of the breadboard, while the third acts as a stop for the perpendicular edge of the breadboard. Thus, the breadboard can be removed from its position and returned with good repeatability.

*Delrin® is a registered trademark of DuPont Polymers, Inc.

- Four Size Options Available for Benchtop Vibration Isolation

- Available Mounting Options:

- 1/4"-20 (M6) Tapped to Directly Attach to a Breadboard

- Adhesive Mounting Surface to Directly Attach to Untapped Surfaces

- Supplied as Set of Four

- Use Extra Feet to Increase Load Capacity

These Sorbothane mounting feet provide a passive isolation solution for workbench-mounted breadboards. They can also be used to isolate noisy equipment from the optical table or breadboard surface. Unlike our pneumatic benchtop isolation solutions, these solid Sorbothane feet do not require inflation.

The AV4(/M), AV5(/M), and AV6(/M) mounting feet each contain internal 1/4"-20 (M6) threading with four included 1/4"-20 (M6) threaded studs. In contrast, the AV3 mounting feet are not threaded, and are attached to equipment or breadboards using the included double-sided tape. See Table 348B below for the load capacities and dimensions of each isolator. When choosing an isolator, we recommend picking the isolator that offers the largest range of damped frequencies for the specific load being used. For further assistance in choosing the proper Sorbothane isolator, please see the Feet Selection Guide tab above.

Please note that these feet may have silicon residue on their surface from the molding process. Thorlabs offers SB12E Adhesive Felt Sheets to reduce contact between this silicon residue and the work surface. These sheets can be cut to match the size of the sorbothane and easily attached via the adhesive side. The residue can also be removed by wiping the feet with an alcohol-based solvent such as isopropyl alcohol (IPA).

Click to Enlarge

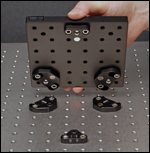

Figure G5.1 KBS98 Kinematic Seats Arranged to Maximize Breadboard Stability

- Build Your Own Kinematic Base System with Our Breadboards

- Magnetically Coupled with High-Strength Rare-Earth Magnets

- Top and Bottom Plates Available Together or Separate

- Turn Any Breadboard into a Kinematic Base Using the 1/4"-20 (M6) Taps

The KBS98 kinematic seats can be used to convert any breadboard into a kinematic platform that can be removed and replaced with a high degree of accuracy. The KBS98 consists of six plates - three top plates and three bottom plates.

Each top plate has an inset ball that will sit in the V-groove of the bottom plate. The three top plates should be attached to the optical breadboard that is being taken out of and put back into an optical setup. The bottom plates have V-groove slots and should be mounted on the stationary optical table or breadboard. The plates should be arranged in a triangular pattern near the corners/edge of the optical breadboard with the V-grooves in the bottom plates aligned so that the three axes defined by the V-grooves intersect at a common point (refer to Figure G5.1). Proper positioning of the plates is necessary in order to maximize the stability of the optical breadboard. If multiple breadboards are going to be substituted in and out of the same place, additional top (KBS98T) and bottom (KBS98B) plate sets are available below.

Products Home

Products Home

Zoom

Zoom

Feet

Feet