Optical Table and Active Isolator Leg Bundles

- 210 mm (8.3″) or 310 mm (12.2") Thick Nexus® Optical Table

- Four Self-Leveling Active Isolation Table Legs

- Optional Sealed Mounting Holes

Please Wait

Features

- Bundle Includes Nexus Optical Table and Active Isolator Table Legs

- Table Sizes from 4' x 6' (1.2 m x 2 m) to 4.8' x 10' (1.5 m x 3 m) Available

- 600 mm (23.6") or 700 mm (27.5") Tall Legs for a Standard 910 mm (35.8") Tabletop Height

- Every Table Individually Tested and Optimized

- 1/2" (12.5 mm) Hole Border for Maximum Usable Area

- Optional Sealed Mounting Holes

- For Use with Earthquake Restraints, Custom Order a Modified Table (Contact Tech Support)

Nexus® Optical Tables and Breadboards

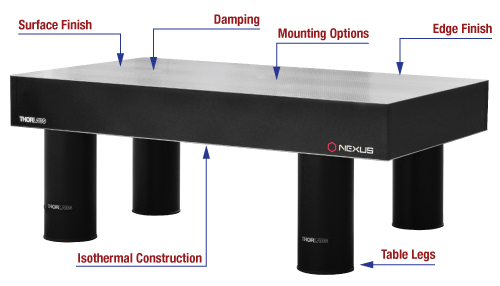

One High Quality Level

Nexus is a single high-quality grade of tables and breadboards manufactured in various sizes by Thorlabs. They are suitable for photonics, imaging, and microscopy applications. Each size is individually tested and optimized. See the Table Vibration Isolation and Construction tabs for more details.

Thorlabs' Nexus® optical table kits feature our Nexus optical tabletops and our active isolation table legs. Kits are available with table sizes from 4' x 6' (1.2 m x 2 m) to 4.8' x 10' (1.5 m x 3 m) and table thicknesses of 210 mm (8.3") or 310 mm (12.2"). They are paired with 600 mm (23.6") or 700 mm (27.5") tall legs for a standard 910 mm (35.8") tabletop height.

Tabletop

Nexus tabletops feature all-steel construction, excellent thermal stability, and broadband damping optimized for each table size. The 5 mm thick stainless steel top and bottom skins have a matte finish and the top skin is precision-machined with a surface flatness of ±0.1 mm over any 1 m2 area. The table has 1/4"-20 (M6) mounting holes on 1" (25 mm) centers with a 0.5" (12.5 mm) border at the edge of the table. Optional sealed mounting holes are available.

Support Legs

Thorlabs' active vibration isolation optical table supports contain an isolation system that effectively isolates the optical table from vertical and horizontal vibrations throughout the critical 3 to 50 Hz frequency range since most common large-amplitude sources of vibrations found in laboratories vibrate within this range of frequencies. The vertical vibrations are isolated from the optical table by a dual-chamber pneumatic isolation system that requires a constant source of compressed air, such as an air compressor (sold separately). If the source of compressed air is removed, the optical table will lower until it securely rests on the large-diameter cylindrical optical table supports, albeit the table will no longer be isolated from floor vibrations. For all table kits sold on this page, kits ending with HK and CK are paired with our PTS603 700 mm (27.5") tall legs, and kits ending with WK and QK are sold with our PTS602 600 mm (23.6") tall legs.

Please note: We also offer earthquake restraints for lab safety in earthquake zones. All tables require modification to accept earthquake restraints prior to shipment. Please contact Tech Support to order an optical table equipped with the necessary alterations. Tables, once they are manufactured and shipped, cannot be retrofitted to accept earthquake restraints.

| Specifications | ||

|---|---|---|

| Construction | ||

| Table Thickness | 210 mm (8.3") or 310 mm (12.2") | |

| Flatness of Top Skin | ±0.1 mm (±0.004") Over Any 1 m2 | |

| Construction | Symmetrical Isotropic Construction in All Axes | |

| Top and Bottom Plates | 5 mm (0.20") Thick Ferromagnetic Stainless Steel | |

| Core Construction | High-Density Plated Steel Honeycomb, 0.26 mm Thick | |

| Damping | Proprietary Optimized Broadband Damping | |

| Side Panels | Rigid Steel Box Section | |

| Side Trim Finish | Matte Black Linoleum, 2 mm Inset from Table Surface | |

| Top Surface Finish | Machined Matte Finish | |

| Mounting Holes | Imperial | Metric |

| Threads and Spacing | 1/4"-20 Tapped Holes on 1" Centers | M6 Tapped Holes on 25 mm Centers |

| Distance from Edge to First Holes | 0.5" from Table Edge on all Sides | 12.5 mm from Table Edge on all Sides |

| Maximum Screw Depth | Standard Holes: Total Table Thickness Minus 5 mm (23.5 mm for Outer Border Holes) Sealed Holes: 25 mm (23.5 mm for Outer Border Holes) |

|

| Performancea | ||

| Maximum Dynamic Deflection Coefficientb | <0.4 x 10-3 | |

| Maximum Relative Tabletop Motionb | <0.14 nm (5.5 x 10-9 in.) | |

| Deflection Under Load (Stiffness)b, c | 210 mm (8.3") Thick Table: <1.7 μm for a 150 kg (330 lb) Load 310 mm (12.2") Thick Table: <1.2 μm for a 150 kg (330 lb) Load |

|

Unpackaged Table Weights

Unpacked Imperial Table Dimensions & Weight

| Item # | Dimensions (W x L x H) |

Weight | Mass |

|---|---|---|---|

| T46HK | 4' x 6' x 8.3" | 932.6 lbs | 423 kg |

| T48HK | 4' x 8' x 8.3" | 1175 lbs | 533 kg |

| T48WK | 4' x 8' x 12.2" | 1307 lbs | 593 kg |

| T510WK | 4.8' x 10' x 12.2" | 1786 lbs | 810 kg |

Unpacked Metric Table Dimensions & Mass

| Item # | Dimensions (W x L x H) |

Mass | Weight |

|---|---|---|---|

| T1020CK | 1 m x 2 m x 210 mm | 397 kg | 875.2 lbs |

| T1220CK | 1.2 m x 2 m x 210 mm | 445 kg | 981.1 lbs |

| T1225QK | 1.2 m x 2.5 m x 310 mm | 600 kg | 1323 lbs |

| T1530QK | 3 m x 1.5 m x 310 mm | 816 kg | 1799 lbs |

Dynamic Deflection Coefficient

The dynamic deflection coefficient is a figure of merit for optical tables that is derived from the measurement of the optical table's compliance. Physically, the dynamic deflection coefficient can be interpreted as a measure of the table's motion when subjected to vibrations.

where Q is the amplification of the tables response to a vibrational source at a specific frequency (f) of the optic table. Q is calculated by dividing the compliance at the optical table resonance frequency by the theoretical compliance of an ideal rigid body. The maximum dynamic deflection coefficient is usually due to the response of the optical table at its first natural resonance frequency. Nexus® optical tables feature proprietary optimized damping mechanisms to limit the value of Q at the table's natural resonances.

Relative Tabletop Motion

The relative tabletop motion is the relative displacement of any two points on the optical table surface due to environmental vibrations transmitted through the optical table supports. The maximum relative tabletop motion is the worst case relative displacement; for a rectangular optical table, the two points that produce the worst case results are generally located at the corners of the optical table. The measurement reported in the specifications table was taken in a quiet laboratory environment (PSD <10-9 g2/Hz). The optical table supports used to support the optical table had a transmissibility less than 0.01 for frequencies greater than 10 Hz.

Deflection Under Load

The deflection under load is a measure of the stiffness of the optical table. The stiffness of an optical table can be quantified by placing a load at the center of the optical table and measuring the deflection of the optical table surface, which will have a parabolic shape. The specification reported in the table is the relative vertical displacement between the center and edge of the optical table.

Video 27A Simplified Nexus Table Construction

Note: For Illustrative Purposes Only. Not a Representation of the Nexus Tables Construction Sequence

Nexus® Optical Tables and Breadboard Manufacturing

- Experienced In-House Design Engineers Create Models and Production Drawings

- Dedicated Tables Manufacturing Facilities for Repeatable and Consistent Production

- In-House Vibration Transmissibility and Compliance Testing

- In-House Welding and Fabrication

- Custom Design Capabilities for Unique Optical Table and Breadboard Solutions

- Lean Manufacturing:

- Cross-Training Allows Staff to Meet Production Demands

- Use of Current Technology Leads to Increased Quality

- Efficient Organization Leads to Time Savings for Customers

Our team has over 25 years of experience designing optical tables, breadboards, and related accessories. We leverage this experience to ensure that our Nexus® honeycomb optical tables and breadboards always meet two basic design goals: the natural resonances of the table should be as high as possible (well above the frequency of ambient environmental vibrations) and the table should be well damped (to quickly damp vibrations caused by equipment on the surface). To meet these goals, our engineers use a variety of tools to refine their designs, such as finite element analysis (FEA) and SolidWorks. FEA allows our engineers to evaluate various materials and to identify possible unwanted material stresses. SolidWorks is employed to build 3D models of every design.

Click to Enlarge

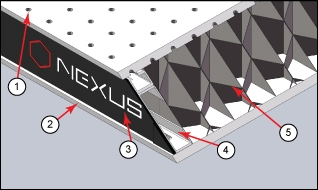

Figure 27C Nexus Table / Breadboard Cross Section, showing the (1) Top Skin, (2) Bottom Skin, (3) Side Panels, (4) Side Rails, and (5) Honeycomb Core

Click to Enlarge

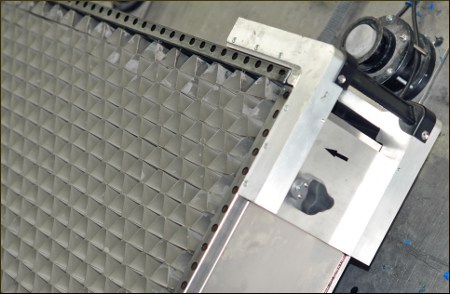

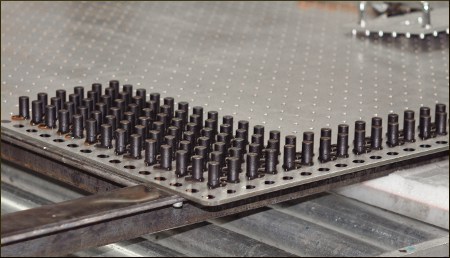

Figure 27B Honeycomb Core of a Nexus Table During Manufacturing

Every Nexus optical table and breadboard is designed to be isotropic and symetrical in X, Y, and Z. For optimal thermal stability, only steel components are used in construction; no wood or plastic is used. Each table includes precision machined top and bottom mounting skins, an uninterrupted honeycomb core, and four side panels with finishing trim. See Video 27A for a simplified illustration of how our tables are assembled. For more details on each step in the process, read this tab.

Precision Steel Construction for Thermal Stability

Thorlabs' Nexus tables and breadboards feature all-steel construction, including 5 mm thick top and bottom skins and a 0.26 mm thick precision formed and welded steel honeycomb core. The core is geometrically formed using accurate pressing tools, and geometric pitch is retained by using welded flat shims. The honeycomb core in our Nexus tables and breadboards extends from the top skin to the bottom skin without intermediate layers, leading to a stiffer, more thermally stable product.

The key aspect of the thermally stable Nexus design is symmetrical isotropic steel construction in all axes. Steel components expand and contract similarly, maintaining flatness during changes in temperature. The steel core extends from top to bottom skin without intermediate plastic or aluminum spill management structures that reduce the overall stiffness of the product and introduce a higher coefficient of thermal expansion. Steel side panels are used rather than wood, which can introduce environmental instability due to susceptibility to moisture.

Click to Enlarge

Figure 27D Heat-Shrink Packaging Being Applied Over a Nexus Optical Table Prior to Shipment

Machined Finish with Minimized Contamination Packaging

Automated Finishing Process

Our Nexus tables and breadboards feature an automated orbital machined matte finish that is significantly smoother and flatter than our previous product line. The improved surface finish achieves ±0.1 mm (±0.004") flatness over any 600 mm x 600 mm area. Large radius corners are incorporated into the design, resulting in less pointed edges for lab safety.

Click to Enlarge

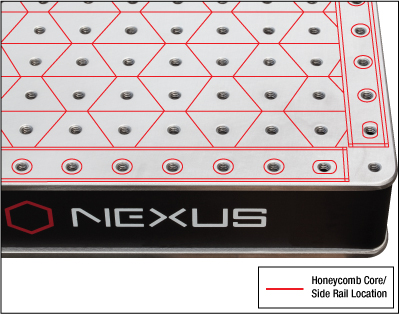

Figure 27E Diagram showing the location of the honeycomb core and side panels, which do not intersect with any screw holes.

Sealed Edges with Anti-Static Packaging

All optical tables ship with a heat-shrink film that protects the table from most contaminants, such as dust, from entering the product during shipment. For additional protection, we offer an optional finishing and packaging service that is suitable for customers that want to minimize the presence of airborne contaminants on the interior and exterior surfaces of the table or breadboard. This includes anti-static packaging, which has a metallic foil inner layer protected by a heat shrink film outer cover, and gap-free edge panel construction to reduce static charge and prevent dust from entering the product.

Mounting Hole Options and Pattern

Individually Tapped, Countersunk Mounting Holes

Prior to bonding the components of the table, each mounting hole in the top surface is tapped and slightly countersunk to ensure that components mounted to the table sit flat. The mounting holes are then cleaned and sealed on the bottom with vinyl film discs (non-sealed models) or sealing cups (sealed hole models, see the Sealed Mounting Holes section). The vinyl film is easily punctured when using a hole for the first time. Cap screws can be finger tightened into the mounting holes of all Nexus tables and breadboards.

Reduced Hole Pattern Border

Our top surface hole patterns extend to the edge of the table or breadboard with only a 12.5 mm (0.5”) border, equal to half of a hole-to-hole spacing. This increases the usable area of the table and improves mounting option flexibility.

Click to Enlarge

Figure 27F Nylon Sealing Cups Installation During Manufacturing

Increased Screw Depth and Optional Sealed Holes

Our custom-designed core maker produces precision formed and welded honeycomb core strips. The core is shaped and installed so that it does not intersect with any screw holes (see Figure 27E), allowing screws to be inserted far into the table, all the way to the bottom skin (for non-sealed-hole models). See the Specs tab for specific screw depth specifications, including outer border holes.

Sealed Mounting Holes

Tables and breadboards can be manufactured with nylon sealing cups glued to the underside of the top skin (see Figure 27F) for liquid spill management. Sealed hole tables are available in all sizes and thicknesses, and the maximum screw depth is 1" (25.4 mm).

Mounting Holes on the Bottom Skin

Our breadboards feature at least four mounting holes in the base skin, permitting the secure attachment of standard or vibration isolating feet and allowing more flexibility for integrating breadboards onto tables or into setups in addition to using breadboard stands.

Click to Enlarge

Figure 27G Optical tables and breadboards are tapped using a high-speed drilling machine.

Click to Enlarge

Figure 27H The surfaces of our tables and breadboards are sanded in our finishing machine.

| Active Vibration Isolator Specificationsa | |||

|---|---|---|---|

| Kit Item # | T48WK T510WK T1225QK T1530QK |

T46HK T48HK T1020CK T1220CK |

|

| Leg Item # | PTS602 | PTS603 | |

| Leg Height | 600 mm (23.6") |

700 mm (27.5") |

|

| Vertical Resonant Frequency | 1.35 Hz | ||

| Horizontal Resonant Frequency | 1.0 Hz | ||

| Vertical Transmissibility at Resonance | 10 dB | ||

| Horizontal Transmissibility at Resonance | 12 dB | ||

| Vertical Transmissibility at 5 Hz | -20 dB (90% Isolation) | ||

| Vertical Transmissibility at 10 Hz | -32.5 dB (97.5% Isolation) | ||

| Horizontal Transmissibility at 5 Hz | -24 dB (94% Isolation) | ||

| Horizontal Transmissibility at 10 Hz | -30 dB (97% Isolation) | ||

| Maximum Load Capacity (Set of Four) | 2500 kg (5500 lbs) | ||

| Height Adjustment Range | -13 mm, +5 mm (-0.51", +0.2") | ||

| Self Leveling Repeatability | 0.5 mm (±0.02") | ||

| Air Pressure (Maximum) | 80 psi (551 kPa) | ||

| Finish | Black Paint | ||

| Vibration Sources and Their Approximate Contributions | ||

|---|---|---|

| Types | Frequency (Hz) | Typical Amplitude (inches) |

| Air Compressors | 4 – 20 | 10-2 |

| Handling Equipment | 5 – 40 | 10-3 |

| Pumps | 5 – 25 | 10-3 |

| Building Services | 7 – 40 | 10-4 |

| Foot Traffic | 0.5 – 6 | 10-5 |

| Elevators | Up to 40 | 10-3 to 10-5 |

| Building Motion | 46/Height in meters | 10-1 |

| Building Pressure Waves | 1 – 5 | 10-5 |

| Railroada | 5 - 20 | +/-0.15g dB |

| Highway Traffica | 5 - 100 | +/-0.001g dB |

Transmissibility

An optical table system is subjected to continuous vibrational impulses from the laboratory floor. These vibrations may be caused by large machinery within the building or even by wind or traffic-excited building resonances (swaying). Transmissibility is a measure of the isolators efficiency at damping out these vibrations and is defined as the ratio of the amplitude of the transmitted vibration to that of the forcing vibration.

Other common ways to represent this ratio are:

Percent of isolation = (1 - transmissibility ratio) x 100 or

Isolation in dB = 20 x log(transmissibility ratio).

At resonance, the system amplifies the input vibration so that the transmissibility ratio is greater than one. The transmissibility ratio is dependent on several factors; for instance the ratio will be dependent on the load placed on the isolators. Remember that the isolators only damp vibrations transmitted through the legs of the frame from the floor; air handling systems are often a significant source of vibration that is transmitted to the work surface through the air. As a result, in applications particularly sensitive to vibrations a comprehensive evaluation of the environment is recommended before choosing a vibration isolation platform. For more information on this topic please see our Vibration Isolation Tutorial.

Optimized Damping

Broadband Damping

The most important feature of an optical table or breadboard is its resonant frequency. Since resonant frequency and vibration amplitude are inversely related, the resonant frequency should be as high as possible to minimize vibration intensity. Nexus tables and breadboards are broadband damped over a specific range of frequencies. For improved performance, the damping is optimized for each size of table and breadboard offered.

We have performed extensive testing to optimize the thickness/size ratio of our tables. Larger sized tables (at least 10' or 3 m long) are offered with a standard 12.2" (310 mm) or 18.1" (460 mm) thickness for stability. Smaller sizes are available in both 8.3" (210 mm) and 12.2" (310 mm) thicknesses; they can be custom ordered in larger sizes.

Compliance

The most widely used transfer function for the vibrational response of an optical table is compliance. In the case of a constant (static) force, compliance is defined as the ratio of the linear or angular displacement to the magnitude of the applied force. In the case of a dynamically varying force (vibration), compliance is defined as the ratio of the excited vibrational amplitude (angular or linear displacement) to the amplitude of the force causing the vibration. Any deflection of the tabletop is evident by the change in relative position of the components mounted on the table surface. Therefore, by definition, the lower the compliance value is, the closer the optical table is to meeting the primary goal of optical table design: minimized deflection. Compliance is frequency dependent and is measured in units of displacement per unit force (meters per newton).

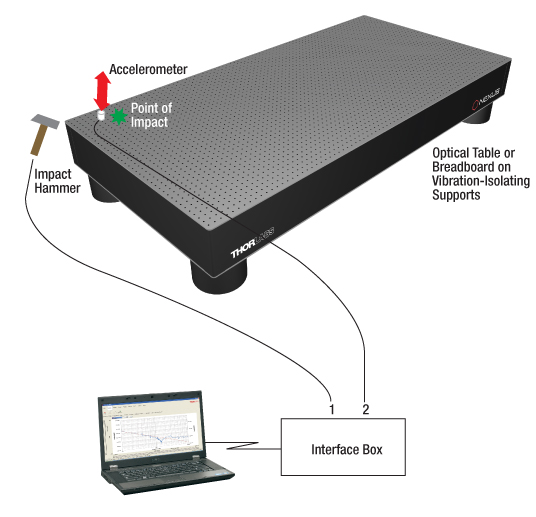

Click to Enlarge

Figure 118A Compliance Test Schematic

See the Vibration Isolation Tutorial for more information on compliance.

Compliance Measurement Procedure

An impulse hammer is used to apply a measured force to the top surface of the table or breadboard, and transducers attached to the surface detect the resultant vibrations (see Figure 118A). The signals from the transducers are interpreted by the analyzer and used to produce a frequency response spectrum (i.e., a compliance curve). During the development phase of an optical table, compliance curves are recorded at many points on the tabletop; however, the compliance is always greatest at the corners. The compliance curves and data published by Thorlabs are taken with the sensor located approximately 6" (150 mm) from the corner of the tabletop (closer to the edge for small breadboards), with the point of impact just inboard of the sensor. This test location represents the worst case data.

Click to Enlarge

Figure 118B Nexus Table Compliance Testing

Test Results

| Posted Comments: | |

Mark Morris

(posted 2024-05-02 14:13:00.197) Missing data regarding the positional tolerance of the breadboard pattern in optical tables. spolineni

(posted 2024-05-08 10:56:15.0) Thank you for contacting us. The tolerance on the cut skin dimensions is +/- 0.25mm (0.01in). This is also the tolerance between the edge of the skin and the first tapped hole. For subsequent holes, we maintain a positional tolerance of ±0.2mm (0.0078in). This means that the measurement should be taken from one hole to the next, rather than from other edges of the skin. This is because we aim to guarantee an accurate matrix, and the edges of the skin could have a slight error. Jiannis Taxidis

(posted 2022-11-29 14:34:47.997) Dear Thorlabs,

Is it possible to get a custom-sized table? I am interested in a 4'x7'x12.2" table. If doable, could you please provide me with a quote (including delivery in Toronto, Canada)? Thank you so much!

Best

Jiannis Taxidis JReeder

(posted 2022-11-30 06:59:40.0) Thank you for contacting us. Your local technical support team will reach out to you to confirm some additional specifications before providing you with a quotation for this custom table. Requests for custom optical tables can also be requested through our web portal here: https://www.thorlabs.com/CustomTables.cfm angelo mottolese

(posted 2022-09-06 10:32:42.027) Good morning Thorlabs!

How safe is it to lean on the optical table like a normal table?

Is it important to avoid unnecessary pressures?

Thanks in advance, I wish you a great day! cwright

(posted 2022-09-06 10:13:14.0) Response from Charles at Thorlabs: Thank you for your query. We would advise against leaning on the optical table. Pressing on the table would depress a valve, causing the isolator to lose air and the table to lower. The isolator then needs to refill it from the supply. Our table frames can be equipped with lean bars for this purpose. Son Nguyen

(posted 2022-07-14 13:11:06.827) Dear Sir

I am Son Nguyen from Viet Nam

We want to buy your product - Optical Table- T1020CK

https://www.thorlabs.com/thorproduct.cfm?partnumber=T1020CK

Please quote us the price and cluding shipping cost and leatime.

Best Regards,

Mr. Son Nguyen

Tel: +84 963653625

Email: sales.thietbiquanghoc@gmail.com cwright

(posted 2022-07-15 10:58:48.0) Response from Charles at Thorlabs: Thank you for contacting us. Your local sales team will reach out to you with a quote. Our sales offices can also be reached through their contact details at the following link: https://www.thorlabs.com/locations.cfm Harrivin Vijayakumaran

(posted 2020-07-16 01:10:50.083) Hi, I am looking to purchase your T1020CK and T1530QK pneumatic tables. I have sent in an email to your tech support requesting for help in my design, however I do have some urgent questions. Is there anyone I could contact via teleconference in short notice? cwright

(posted 2020-07-16 10:23:58.0) Response from Charles at Thorlabs: Hello and thank you for contacting us. Your email has been picked up by your local technical support team and one of our representatives has reached out to you. lw493

(posted 2017-01-12 11:20:21.49) Would it be possible to find out if you have any second hand tables (T1020CK, T1220CK, T1225QK or T1530QK) available at a reduce price?? awebber-date

(posted 2017-01-18 04:41:39.0) Response from Alex at Thorlabs: I’m afraid we don’t offer second hand tables at a reduced price. Since these tables have a lifetime warranty, we find that they are almost never returned. If you are setting up a new lab, or are making a large order, it may be worth looking at our discount policy. yzhang

(posted 2016-08-16 11:01:47.237) Dear Sir/Madam,

What is the typical delivery time for optical table? If we order one optical table and the Availability/Ship status showed "Today", does it mean it could be shipped out today? Or there will be some manufacturing time? Thanks!

Regards,

Yi msoulby

(posted 2016-08-17 09:11:58.0) Response from Mike at Thorlabs: Manufacturing is not required when the status shows “Today”. This means that the product is on the shelf and ready for dispatch; if the items are too large or heavy for a normal courier, a booking may be required with a dedicated freight company, which we can arrange on your behalf. david.panak

(posted 2016-01-13 08:26:47.623) would like to have a option to buy a table top and passive legs together as a single part number besembeson

(posted 2016-01-14 03:18:00.0) Response from Bweh at Thorlabs USA: Thanks for contacting Thorlabs. We will review this suggestions. In the meantime, we can send you a special bundle quotation. I will contact you. ahmetdiril

(posted 2015-01-12 09:48:23.307) planning to buy optical tables with isolator legs. questions: 1. What is difference btw sealed holed and not sealed hole? Does it mean the hole has some depth (sealed) and, goes through the table(non sealed)? 2. we were offered to buy a compressor for the legs, which is OK. But can we also use these legs and table without compressor? meaning without giving pressurized air? rcapehorn

(posted 2015-01-13 09:56:10.0) Response from Rob at Thorlabs: Our sealed tables utilise individual Nylon based sealing cups, underneath each of the tapped holes on the top mounting surface. These cups prevent any liquid spills from entering the void within the table. They will also restrict the maximum screw depth to 25mm.

You can use our active system without any air supply. However we would advise against it as the whole system will simply be resting on the leg tubes and will no longer be isolated from vibrations. If you are not interested in vibration isolation, I would suggest changing your leg choice to one of our ridged leg systems. For example, PTL702. szymon

(posted 2014-11-18 08:49:55.48) T1020C Nexus Optical Table has on the bottom side two sets of M6 threaded holes with span:

(1) 660 x 1125 mm designed for PTS603 legs,

(2) 710 x 1570 mm designed for TF1020A7 table frame.

Is it also possible to use holes (2) with PTS603 legs? msoulby

(posted 2014-11-19 03:28:49.0) Response from Mike at Thorlabs: We will contact you directly to discuss the specifications of the custom table that you require in more detail. gnarlock

(posted 2013-06-05 17:15:04.093) Can you please tell me what the weight of this table is? tcohen

(posted 2013-06-06 14:37:00.0) Response from Tim at Thorlabs: The weight of the table top itself (T48H) is approximately 382kg. We will add this information to the website shortly. |

Products Home

Products Home

Click to Enlarge

Click to Enlarge

Optical Table and Leg Kits

Optical Table and Leg Kits