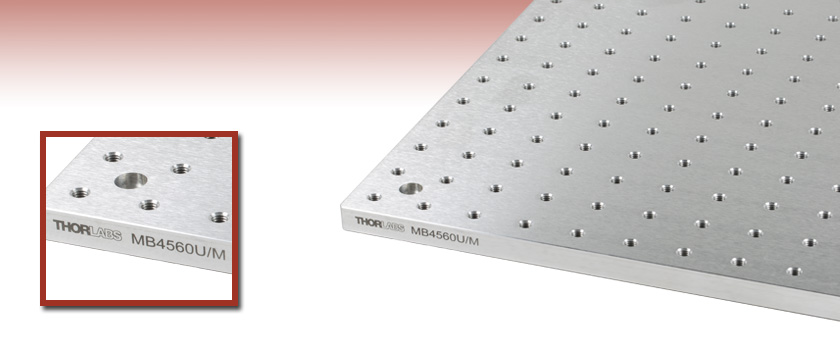

Unanodized Solid Aluminum Optical Breadboards

- Unanodized Finish Ideal for Customization

- Through-Tapped Mounting Holes

- Custom Sizes Available

Counterbored Ø1/4"

(M6) Mounting Holes

MB4560U/M

450 mm x 600 mm x 12.7 mm, M6 Taps

Please Wait

| Specification | Imperial Boards | Metric Boards |

|---|---|---|

| Material | 5083 Aluminum Tooling Plate | |

| Finish | Precision Ground, Matte Finish | |

| Breadboard Thickness | 0.5" | 12.7 mm |

| Flatness | ±0.006" over 1 ft2 | ±0.15 mm over 0.09 m2 |

| Hole Size and Spacing | 1/4"-20 Tapped Holes on 1" Centers |

M6 Tapped Holes on 25 mm Centers |

| Distance from Edge to First Hole |

0.5" on All Sides | 12.5 mm on All Sides |

| Number of Counterbored Holesa | Four 1/4" Located at Corners - Inset 1" | Four M6 Located at Corners - Inset 25 mm |

Features

- Precision Manufactured Unanodized Surface

- Electrically Conductive for Applications Requiring a Common Ground

- Standard Imperial and Metric Breadboard Hole Patterns

- Offset Counterbored Mounting Holes Allow a Full, Uninterrupted, Threaded Hole Matrix

- Larger Breadboards [MB1218U (MB3045U/M) and Larger] Have a Fifth Center-Located

Counterbore Mounting Hole - Double-Density, High-Density Versions, and Custom Sizes Available

- All Boards Stocked for Quick Delivery

These solid aluminum, unanodized, non-magnetic breadboards provide a convenient and cost-effective platform for those wishing to modify a breadboard to suit a specific prototype or experimental need. They are finished with a precision-ground surface and are through-drilled with a standard 1" (imperial) or 25 mm (metric) hole pattern offset 1/2" or 12.5 mm from the edges of the board, respectively. Each breadboard is constructed from 5083 aluminum that has never been anodized for ease of customization. Although the aluminum oxide coating traditionally applied to breadboards minimizes reflectance, it also increases the hardness of the end product, making anodized breadboards more difficult to machine.

Each breadboard features four or five mounting holes, which are counterbored to create an uninterrupted surface for your application. The four standard mounting holes are located at each corner of the breadboard, inset 1" from each edge on imperial breadboards (25 mm on metric). The three largest imperial and metric boards (MB1218U, MB1224U, MB1824U, MB3045U/M, MB3060U/M, and MB4560U/M) have a fifth counterbored mounting hole in the center. Utilizing the center mounting hole increases the mounting options available, reduces stress at the corner mounting holes, and increases rigidity when heavy loads are placed on the boards. The mounting holes may be used to attach the breadboards to optical tables, other breadboards, mounting posts, brackets, or a variety of other surfaces or mounts.

Because the holes are threaded completely through these breadboards, components can be mounted on either side of the breadboards. Ø1.5" Mounting Posts allow for adjustments to the height of the optical axis by mounting the breadboards above the surface of an optical tabletop (or another breadboard). The breadboards can also be mounted vertically using 90° or Vertical Mounting Brackets.

In addition to facilitating customized hole patterns and modifications, the lack of an anodized coating on these breadboards also allows them to be used within a vacuum environment down to 10-6 Torr. Prior to use in a vacuum system, these breadboards will require additional treatment and cleaning. For additional information on preparing these breadboards for vacuum applications, please contact Tech Support.

For other vacuum-compatible options, we offer Passivated Stainless Steel Breadboards, which are stiffer at an equivalent thickness. Black Anodized Aluminum Breadboards are also available in a variety of sizes. The black anodized coating on these breadboards is ideal for limiting stray reflections in an optical system.

Custom Breadboards

We offer a service for custom breadboard orders, with options that include hole pattern and spacing, size, thickness, and anodizing. For a quote, please fill out our custom breadboards form.

| Item # | Dimensions (L x W x T) |

Unpackaged | Packaged Shipping | ||

|---|---|---|---|---|---|

| Mass (kg) | Weight (lbs) | Mass (kg)a | Weight (lbs)a | ||

| MB4U | 4" x 4" x 0.5" | 0.33 | 0.73 | 0.50 | 1.10 |

| MB6U | 6" x 6" x 0.5" | 0.75 | 1.65 | 0.81 | 1.79 |

| MB8U | 8" x 8" x 0.5" | 1.34 | 2.95 | 2.00 | 4.41 |

| MB810U | 8" x 10" x 0.5" | 1.68 | 3.70 | 2.40 | 5.29 |

| MB1012U | 10" x 12" x 0.5" | 2.52 | 5.56 | 3.50 | 7.72 |

| MB12U | 12" x 12" x 0.5" | 3.02 | 6.66 | 4.00 | 8.82 |

| MB1218U | 12" x 18" x 0.5" | 4.54 | 10.01 | 5.84 | 12.86 |

| MB1224U | 12" x 24" x 0.5" | 6.05 | 13.34 | 7.00 | 15.43 |

| MB1824U | 18" x 24" x 0.5" | 9.09 | 20.04 | 11.02 | 24.29 |

| MB1015U/M | 100 mm x 150 mm x 12.7 mm | 0.48 | 1.06 | 0.70 | 1.54 |

| MB1515U/M | 150 mm x 150 mm x 12.7 mm | 0.73 | 1.61 | 0.92 | 2.03 |

| MB2020U/M | 200 mm x 200 mm x 12.7 mm | 1.30 | 2.87 | 2.00 | 4.41 |

| MB2025U/M | 200 mm x 250 mm x 12.7 mm | 1.62 | 3.57 | 1.82 | 4.01 |

| MB2530U/M | 250 mm x 300 mm x 12.7 mm | 2.44 | 5.37 | 3.40 | 7.49 |

| MB3030U/M | 300 mm x 300 mm x 12.7 mm | 2.93 | 6.46 | 3.90 | 8.60 |

| MB3045U/M | 300 mm x 450 mm x 12.7 mm | 4.40 | 9.70 | 5.61 | 12.37 |

| MB3060U/M | 300 mm x 600 mm x 12.7 mm | 5.86 | 12.92 | 6.80 | 14.99 |

| MB4560U/M | 450 mm x 600 mm x 12.7 mm | 8.80 | 19.40 | 10.73 | 23.66 |

| Posted Comments: | |

user

(posted 2024-11-20 13:43:43.607) Hi,

For your unanodised solid aluminium optical breadboards for use in vacuum, what grade of aluminium is used?

Also are they made from cast tooling plate?

Thanks in advance spolineni

(posted 2024-11-29 12:55:22.0) Thank you for your enquiry. The MB Series un-anodised solid aluminium optical breadboards are crafted from 5083 aluminium alloy and make use of cast aluminium speciality plate. I will reach out to you directly to discuss this further. John Travers

(posted 2021-01-14 05:22:49.313) I'd like to use these breadboards in a vacuum system, can you please describe what the additional preperation steps you suggest are? DJayasuriya

(posted 2021-01-14 08:53:18.0) Thank reaching out to us, the additional preparation that we recommend to use in the breadboard in vacuum is to be cleaned with deionised water and then baked within the vacuum environment prior to any experiments. Florian Amrein

(posted 2019-10-29 06:31:31.25) Hello, I would like to submit some drawings for custom made breadboard to get a quote for it. Could you please contact me? Thanks a lot! cwright

(posted 2019-10-29 09:03:29.0) Response from Charles at Thorlabs: Hello Florian, thank you for your interest in our breadboards. Requests for custom items can always be sent to your local technical support team who would be happy to help. I will ask them to reach out to you directly for your drawings. justinjh

(posted 2018-12-10 15:20:58.57) I would like to order a MB6U but with double density holes. Is that possible? AManickavasagam

(posted 2018-12-13 09:12:20.0) Response from Arunthathi at Thorlabs: Thanks for your query. Yes, we are able to offer double density MB6U. We will contact you directly with a quote. |

- Breadboard Sizing: Length x Width x Thickness

- Threading: All Imperial Breadboards Feature 1/4"-20 Threads on 1" Centers

- MB4U, MB6U, MB8U, MB810U, MB1012U, and MB12U Have Four Counterbored Mounting Holes

- MB1218U, MB1224U, and MB1824U Have Five Counterbored Mounting Holes

Products Home

Products Home

Unanodized Standard Series Optical Breadboard

Unanodized Standard Series Optical Breadboard