Polaris® Low Drift Kinematic Platform Mount

- Nine 8-32 (M4) Tapped Holes for Securely Mounting Components

- Matched Actuator Threading Minimizes Drift and Backlash

- Heat Treating Minimizes Temperature-Dependent Hysteresis

- Sapphire Seats Ensure Long-Term Stability

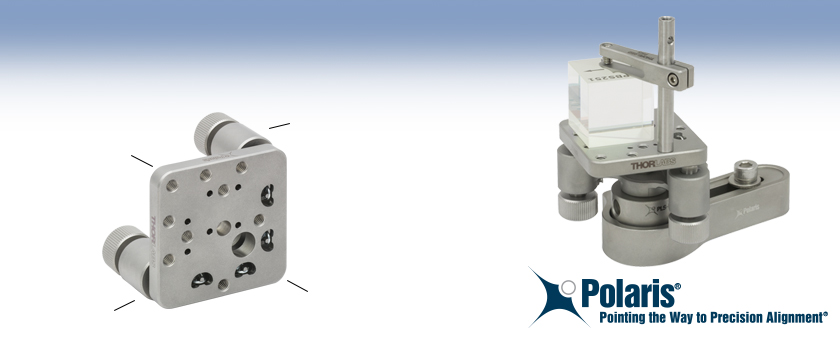

Application Idea

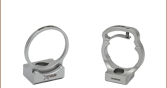

Polaris Platform Mount Shown with Stainless Steel Clamping Arm to Mount 1" Cube Beamsplitter

POLARIS-K1M4

Kinematic Platform Mount

Matched Actuator and Body Pairs

8-32 (M4) Mounting Taps

Sapphire Seats on All Adjusters

Heat-Treated Stainless Steel

Please Wait

Mounts for OEMs

Thorlabs' Polaris Platform Mount was designed to meet the needs of OEM customers. To that end, we are equipped to manufacture these mounts in high volumes and with timed delivery. Additionally, we can design and manufacture modified versions of these mounts that have different tapped mounting holes, clearance holes or platform sizes. For example, we have produced similar platform mounts with a 2" x 2" platform size and a different 8-32 hole pattern. To find out more about our OEM capabilities, please contact Tech Support.Features

- Machined from Heat-Treated Stainless Steel with Low Coefficient of Thermal Expansion (CTE)

- Mounting Platform with #8 (M4) Through Hole and Array of 8-32 (M4) Tapped Holes

- Hardened Stainless Steel Ball Contacts with Sapphire Seats for Durability and Smooth Movement

- Matched Actuator and Back Plate Provide Smooth Kinematic Adjustment

- Extensive Testing Guarantees <2 μrad Deviation after 12.5 °C Temperature Cycling (See Test Data Tab for Details)

- Passivated Stainless Steel Surface Ideal for Vacuum and High-Power Laser Cavity Applications

- Custom Mounting Hole Patterns and Platform Sizes Available by Contacting Tech Support

The Polaris® Kinematic Platform Mount is the ultimate solution for applications requiring stringent long-term alignment stability. The platform surface features an array of nine 8-32 (M4) tapped holes and one #8 (M4) clearance hole for mounting optomechanical components. Alignment pin holes, located on either side of the clearance hole and two of the taps, allow for precise alignment of components mounted to the surface of the platform.

Design

Machined from heat-treated stainless steel, Polaris mounts utilize precision-matched adjusters with ball contacts and sapphire seats to provide smooth kinematic adjustment. As shown on the Test Data tab, the kinematic platform mount has undergone extensive testing to ensure high-quality performance. The Polaris design addresses all of the common causes of beam misalignment; please refer to the Design Features tab for detailed information.

Post Mounting

Polaris mirror mounts are equipped with #8 (M4) counterbores for post mounting. Select mounts also include Ø2 mm alignment pin holes around the mounting counterbore, allowing for precision alignments when paired with our Ø1" Posts for Polaris Mirror Mounts. See the Usage Tips tab for more recommendations about mounting configurations.

Cleanroom and Vacuum Compatibility

The POLARIS-KIM4(/M) is designed to be compatible with cleanroom and vacuum chamber applications. See the Specs tab and the Design Features tab for details.

Click to Enlarge

POLARIS-K1M4 Top Plate

| Item # | POLARIS-K1M4(/M) |

|---|---|

| Number of Adjusters | Two |

| Adjuster Drive | 5/64" Hex with Removable Knobs and Ø0.07" Side Adjustment Holes |

| Adjuster Pitch | 100 TPI Matched Actuator/Body Pairs |

| Measured Adjuster Lock Mechanical Resolution per Adjustera |

5 µrad (Typical); 2 µrad (Achievable) |

| Measured Point-to-Point Mechanical Resolution per Adjuster (Bidirectional Repeatability) |

5 µrad (Typical); 2 µrad (Achievable) |

| Resolutionb | ~7.7 mrad/rev |

| Mounting Holes on Mounting Platform | Nine 8-32 (M4) Tapped Holes Ø0.20" (Ø5.1 mm) Clearance Hole for #8 (M4) Cap Screws |

| Mechanical Angular Range (Nominal) | ±4° |

| Beam Deviationc After Thermal Cycling | <2 µrad |

| Maximum Front Plate Load Capacity (Torque / Weight / Mass) |

Horizontal Platform: 5.0 lb-in (0.56 N-m) / 6.50 lb / 2.95 kg Vertical Platform: 3.5 lb-in (0.40 N-m) / 4.25 lb / 1.59 kg |

| Post Mountingd | Vertical Mounting: Two #8 (M4) Counterbores Horizontal Mounting: One #8 (M4) Counterbore |

| Alignment Pin Holese | Two at Select Platform Mounting Holes (See Drawing to the Right) Two at Each Post Mounting Counterbore |

| Vacuum Compatibilityf | 10-9 Torr at 25 °C with Proper Bake Out; 10-5 Torr at 25 °C without Bake Out Grease Vapor Pressure: 10-13 Torr at 20 °C ,10-5 Torr at 200 °C Epoxy Meets Low Outgassing Standards NASA ASTM E595,Telcordia GR-1221 |

| Operating Temperature Range | -30 to 200 °C |

Polaris® Kinematic Mounts Test Data

The Polaris Platform Mounts have undergone extensive testing to ensure high-quality performance. A POLARIS-B1G fixed mount with a mirror glued in was attached to the POLARIS-K1M4 platform mount. This assembly was then mounted to a Ø1" stainless steel post, and then secured to a stainless steel optical table in a temperature-controlled environment. A beam from an independently temperature-stabilized laser diode was reflected by the mirror onto a position sensing detector.

Positional Repeatability After Thermal Shock

Purpose: This testing was done to determine how reliably the mount returns the optic, without hysteresis, to its initial position. These measurements show that the alignment of the optical system is unaffected by the temperature shock.

Procedure: The temperature of each mount tested was raised to 37.5 °C and maintained for a given soak time. Then the temperature of the mirror mount was returned to the starting temperature. The results of these tests are shown below.

Results: As can be seen in the plots below, when the Polaris mounts were returned to their initial temperature, the angular position (both pitch and yaw) of the optics returned to within 2 µrad of its initial position. The performance of the Polaris was tested further by subjecting the mount to repeated temperature change cycles. After each cycle, the mirror’s position reliably returned to within 2 µrad of its initial position.

For Comparison: To get a 1 µrad change in the mount’s position, the 100 TPI adjuster on the Ø1" Polaris mounts needs to be rotated by only 0.05° (1/7200 of a turn). A highly skilled operator might be able to make an adjustment as small as 0.3° (1/1200 of a turn), which corresponds to a 6 µrad change in the mount's position.

Conclusions: The Polaris Mirror Mounts are high-quality, ultra-stable mounts that will reliably return a mirror to its original position after cycling through a temperature change. As a result, the Polaris mounts are ideal for use in applications that require long-term alignment stability.

Several common factors typically lead to beam misalignment in an optical setup. These include temperature-induced hysteresis of the optic's position, crosstalk, drift, and backlash. Polaris mounts are designed specifically to minimize these misalignment factors and thus provide extremely stable performance. Hours of extensive research, multiple design efforts using sophisticated design tools such as finite element analysis software, and months of rigorous testing went into choosing the best components to provide an ideal solution for experiments requiring ultra-stable performance from a kinematic mount.

Thermal Hysteresis

The temperature in most labs is not constant due to factors such as air conditioning, the number of people in the room, and the operating states of equipment. Thus, it is necessary that all mounts used in an alignment-sensitive optical setup be designed to minimize any thermally induced alignment effects. Thermal effects can be minimized by choosing materials with a low coefficient of thermal expansion (CTE), like stainless steel. However, even mounts made from a material with a low CTE do not typically return the optic to its initial position when the initial temperature is restored. All the critical components of the Polaris mounts are heat-treated prior to assembly since this process removes internal stresses that can cause a temperature-dependent hysteresis. As a result, the alignment of the optical system will be restored when the temperature of the mount is returned to the initial temperature.

Crosstalk

Crosstalk is minimized by carefully controlling the dimensional tolerances of the front and back plates of the mount so that the pitch and yaw actuators are orthogonal. In addition, sapphire seats are used at all three contact points. Standard metal-to-metal actuator contact points will wear down over time. The polished sapphire seats of the Polaris mounts, in conjunction with the hardened stainless steel actuator tips, maintain the integrity of the contact surfaces over time.

Drift and Backlash

In order to minimize the positional drift of the mount and backlash, it is necessary to limit the amount of play in the adjuster as well as the amount of lubricant used. When an adjustment is made to the actuator, the lubricant will be squeezed out of some spaces and built up in others. This non-equilibrium distribution of lubricant will slowly relax back into an equilibrium state. However, in doing so, this may cause the position of the front plate of the mount to move. The Polaris mounts use adjusters matched to the body that exceed all industry standards so that very little adjuster lubricant is needed. These adjusters have a smooth feel that allows the user to make small, repeatable adjustments.

Cleanroom and Vacuum Compatibility

The POLARIS-KIM4(/M) is designed to be compatible with cleanroom and vacuum applications. It is chemically cleaned using the Carpenter AAA passivation method to remove sulfur, iron, and contaminants from the surface. After passivation, it is assembled in a clean environment and then double vacuum bagged to eliminate contamination when transported into a cleanroom.

The sapphire contacts are bonded into place using a NASA-approved low outgassing procedure. In addition, DuPont LVP High-Vacuum (Krytox) Grease, an ultra-high vacuum compatible, low outgassing PTFE grease, is applied to the adjusters. These features provide high vacuum compatibility and low outgassing performance. When operating at pressures below 10-5 Torr, we highly recommend using an appropriate bake out procedure prior to installing the mount in order to minimize contamination caused by outgassing. Please note that the 8-32 and M4 cap screws included with the Polaris mounts are not rated for pressures below 10-5 Torr.

Cleanroom-Compatible Packaging

Each vacuum-compatible Polaris mount is packaged within two vacuum bag layers after assembly in a clean environment. The vacuum-tight fit of the bags stabilizes the mount, limiting translation of the front plate due to shocks during transportation. The tight fit also minimizes rubbing against the bag, preventing the introduction of bag material shavings that would contaminate the clean mount.

In the vacuum-sealing process, moisture-containing air is drawn out of the packaging. This eliminates unwanted reactions on the surface of the mount without the need for desiccant materials. The vacuum bags protect the mount from contamination by air or dust during transport and storage, and the double-vacuum bag configuration allows for a straightforward and effective cleanroom entry procedure. The outer bag can be removed outside of the cleanroom, allowing the contaminant-free inner bag to be placed into a clean container and transferred into the cleanroom while retaining the benefits of vacuum-bag packaging. Inside the cleanroom, the mount can be removed from the inner bag when ready for use.

Through thermal changes and vibrations, the Polaris kinematic mirror mounts are designed to provide years of use. Below are some usage tips to ensure that the mount provides optimal performance.

Match Materials

Due to its relatively low coefficient of thermal expansion, stainless steel was chosen as the material from which to fabricate the front and back plates of the Polaris mounts. When mounting, we recommend using components fabricated from the same material, such as our Ø1" Posts for Polaris Mirror Mounts and Non-Bridging Clamping Arms.

Use a Wide Post

The Polaris' performance is optimized for use with our imperial or metric Ø1" Posts and our POLARIS-CA1 or POLARIS-CA25/M clamping arm. These posts are made of stainless steel and provide two lines of contact with the mount, which help confine the bottom of the mount during variations in the surrounding temperature, thereby minimizing potential alignment issues.

Front Plate’s Position

Polaris mounts are designed to allow adjustments of up to 8°. To achieve the best performance, it is recommended that the front plate be kept as parallel as possible to the back plate. This ensures the highest stability of the adjustments.

Mount as Close to the Table’s Surface as Possible

To minimize the impact of vibrations and temperature changes, it is recommended that your setup has as low of a profile as possible. Using short posts will reduce the Y-axis translation caused by temperature variations and will minimize any movements caused by vibrations. In the vertical orientation, the Polaris platform mount can be mounted directly onto a flat surface such as a breadboard using a 8-32 to 1/4"-20 thread adapter (Item # AE8E25E) or M4 x 0.7 to M6 x 1.0 adapter (Item # AE4M6M); the platform cannot be mounted directly to the table horizontally. Using this mounting method, the instability introduced by a post will be eliminated.

Polish and Clean the Points of Contact

We highly recommend that the points of contact between the mount and the post, as well as the post and the table, are clean and free of scratches or defects. For best results, we recommend using a polishing stone to clean the table’s surface and a polishing pad (Item # LF1P) for the top and bottom of the post as well as the bottom of the mount.

Not Recommended

We do not recommend taking the adjusters out of the body, as it can contaminate the threading. This can reduce the fine adjustment performance significantly. Also, do not pull the front plate away as it might stretch the springs beyond their operating range or crack the sapphire seats.

Adjuster Lock Nuts

The Polaris mounts below are compatible with the POLARIS-LN1 lock nuts for long-term stability or applications that are exposed to shock and vibration. The beam can be held on target with the adjuster thumbscrew or hex key while lightly tightening the lock nut by hand or with a thin-head wrench or cone wrench. For applications that require frequent tuning of the adjusters, the lock nuts only need to be lightly tightened by hand to a torque of approximately 4 to 8 oz-in (0.03 to 0.06 N·m). For long term stability, we recommend tightening to a torque of 32 oz-in, which can be achieved by using our TW13 preset torque wrench (sold below). The POLARIS-LN1 lock nuts have a 13 mm hex.

To avoid cross threading the POLARIS-LN1 during installation, place it against the adjuster and "unscrew" the lock nut until you feel a slight drop, then thread the lock nut onto the adjuster (see the animation to the right). Each lock nut is pre-greased with the same ultra-high-vacuum-compatible, low-outgassing PTFE grease as the Polaris mounts and has been tested for adjuster fit.

| Posted Comments: | |

Lucile Sanchez

(posted 2020-01-16 14:53:39.267) Hello,

I am searching an AOM mount plateform wich is quite resistant and your Polaris serie is very stable, but the plateform that you have is only vertical and I am searching one horizontal.. Do you think that you can make one serie for AOM related fixation? That will be broadly used!

Cheers,

Lucile llamb

(posted 2020-01-20 03:35:13.0) Hi Lucile, thank you for your feedback. I have added your idea into our internal product forum for further review. As we have discussed by email, the KM100WFS would be ideal to achieve your desired axes of rotation (pitch and yaw), or a stiffer spring solution could be mounting a right-angle bracket onto the vertically oriented POLARIS-K1M4 mounting platform. |

Thorlabs offers several different general varieties of Polaris mounts, including kinematic side optic retention, SM-threaded, low optic distortion, piezo-actuated, vertical drive, and glue-in optic mounts, a fixed monolithic mirror mount and fixed optic mounts, XY translation mounts, 5-axis kinematic mount, and a kinematic platform mount. Refer to the tables below for our complete line of Polaris mounts, grouped by mount type, optic bore size, and then arranged by optic retention method and adjuster type (or intended application in the case of fixed mounts). We also offer a line of accessories that have been specifically designed for use with our Polaris mounts; these are listed in Table 103G. Note that the tables below list Item # suffixes that omit the "POLARIS" prefix for brevity. Click the photos below for details.

| Table 103B Polaris Mount Adjuster Types | |||||

|---|---|---|---|---|---|

| Side Hole | Hex | Adjuster Knobs | Adjuster Lock Nuts |

Piezo Adjusters | Vertical-Drive Adjusters |

|

|

|

|

|

|

| Table 103C Polaris Kinematic Mounts for Round Optics | ||||

|---|---|---|---|---|

| Optic Retention Method | Side Lock | SM Threaded | Low Distortion | Glue-In |

| Ø1/2" Optics | ||||

| 2 Side Hole Adjusters | - | - | - | -K05C4 -K05G4 |

| 2 Hex Adjusters | -K05S1 | -K05T1 | -K05F1 | - |

| 2 Adjusters with Lock Nuts | -K05S2 | -K05T2 | -K05F2 | - |

| 2 Piezoelectric Adjusters | -K05P2 | - | - | - |

| 2 Vertical Adjusters | -K05VS2 -K05VS2L |

- | - | - |

| 3 Hex Adjusters | -K05 | - | - | - |

| 3 Adjusters with Lock Nuts | - | -K05T6 | -K05F6 | - |

| 3 Adjuster Knobs (Tip/Tilt/Z) & 2 Hex Adjusters (X/Y) |

- | -K05XY | - | - |

| Ø19 mm (3/4") Optics | ||||

| 2 Side Hole Adjusters | -K19S4 | - | -K19F4/M | -K19G4 |

| Ø25 mm Optics | ||||

| 2 Side Hole Adjusters | -K25S4/M | - | -K25F4/M | - |

| Ø1" Optics | ||||

| 2 Side Hole Adjusters | -K1S4 | - | - | -K1C4 -K1G4 |

| 2 Hex Adjusters | -K1E2 -K1-2AH |

-K1T2 | -K1F2 | - |

| 2 Adjuster Knobs | - | -K1T1 | -K1F1 | - |

| 2 Piezoelectric Adjusters | -K1S2P | - | - | - |

| 2 Vertical Adjusters | -K1VS2 -K1VS2L |

- | - | - |

| 3 Side Hole Adjuster | -K1S5 | - | - | - |

| 3 Hex Adjusters | -K1E3 -K1-H |

-K1T3 | - | - |

| 3 Adjuster Knobs | -K1E -K1 |

-K1T | -K1F | - |

| 3 Piezoelectric Adjusters | -K1S3P | - | - | - |

| 3 Adjuster Knobs (Tip/Tilt/Z) & 2 Hex Adjusters (X/Y) |

- | -K1XY | - | - |

| Optic Retention Method | Side Lock | SM Threaded | Low Distortion | Glue-In |

| Ø1.5" Optics | ||||

| 2 Side Hole Adjusters | -K15S4 | - | -K15F4 | - |

| 2 Vertical Adjusters | -K15VS2 -K15VS2L |

- | - | - |

| 3 Adjuster Knobs (Tip/Tilt/Z) & 2 Hex Adjusters (X/Y) |

- | -K15XY | - | - |

| Ø50 mm Optics | ||||

| 2 Side Hole Adjusters | -K50S4/M | - | -K50F4/M | - |

| Ø2" Optics | ||||

| 2 Hex Adjusters | -K2S2 | -K2T2 | -K2F2 | - |

| 2 Adjuster Knobs | -K2S1 | -K2T1 | -K2F1 | - |

| 2 Piezoelectric Adjusters | -K2S2P | - | - | - |

| 2 Vertical Adjusters | -K2VS2 -K2VS2L |

- | - | - |

| 3 Hex Adjusters | -K2S3 | -K2T3 | -K2F3 | - |

| 3 Adjuster Knobs | -K2 | -K2T | -K2F | - |

| Ø3" Optics | ||||

| 2 Side Hole Adjusters | -K3S4 | - | - | - |

| 3 Side Hole Adjusters | -K3S5 | - | - | - |

| Ø4" Optics | ||||

| 2 Side Hole Adjusters | - | - | -K4F4 | - |

| Ø6" Optics | ||||

| 2 Side Hole Adjusters | - | - | -K6F4 | - |

| Table 103D Polaris XY Translation Mounts for Round Optics | ||

|---|---|---|

| Optic Retention Method | SM Threaded | Representative Photos |

| Ø1/2" Optics |   |

|

| 2 Hex Adjusters (X/Y) | -05CXY | |

| -05XY | ||

| 3 Adjuster Knobs (Tip/Tilt/Z) & 2 Hex Adjusters (X/Y) |

-K05XY | |

| Ø1" Optics | ||

| 2 Hex Adjusters (X/Y) | -1XY | |

| 3 Adjuster Knobs (Tip/Tilt/Z) & 2 Hex Adjusters (X/Y) |

-K1XY | |

| Ø1.5" Optics | ||

| 2 Hex Adjusters (X/Y) & 3 Adjuster Knobs (Tip/Tilt/Z) |

-K15XY | |

| Table 103E Polaris Fixed Mounts for Round Optics | ||||||

|---|---|---|---|---|---|---|

| Optic Retention Method | Side Lock | Low Distortion |

Glue-In | Representative Photos |

||

| Ø1/2" Optics |     |

|||||

| Optimized for Mirrors | - | -B05F | -C05G | |||

| Optimized for Beamsplitters | -B05S | - | -B05G | |||

| Optimized for Lenses | - | - | -L05G | |||

| Ø19 mm (Ø3/4") Optics | ||||||

| Optimized for Mirrors | -19S50/M | - | - | |||

| Ø1" Optics | ||||||

| Optimized for Mirrors | - | -B1F | -C1G | |||

| Optimized for Beamsplitters | -B1S | - | -B1G | |||

| Optimized for Lenses | - | - | -L1G | |||

| Ø2" Optics | ||||||

| Optimized for Mirrors | - | -B2F | -C2G | |||

| Optimized for Beamsplitters | -B2S | - | - | |||

| Table 103F Polaris Kinematic 1.8" x 1.8" Platform Mount | ||

|---|---|---|

| Optomech Retention Method | Tapped Holes & Counterbores |

|

| 2 Adjuster Knobs | -K1M4(/M) | |

| Table 103G Accessories for Polaris Mounts | |

|---|---|

| Description | Representative Photos |

| Ø1/2" Posts for Polaris Mounts |  |

| Ø1" Posts for Polaris Mounts | |

| Non-Bridging Clamping Arms |  |

| 45° Mounting Adapter |  |

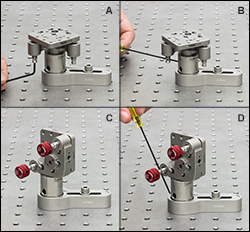

Click to Enlarge

Methods of Adjusting the Polaris Platform Mount:

A: 5/64" or 2.0 mm Hex Key in the End of the Adjuster

B: 1/16" or 1.5 mm Balldriver Through Adjuster Side Holes

C: HKTS-5/64 Hex Knobs in the Adjuster

D: Hex Knobs with Side Hole Fine Adjustment

- 2-Adjuster, Hex-Driven Design

- 100 TPI Matched Actuator/Body Pairs

- ±4° Mechanical Angular Range

- ~7.7 mrad/rev Resolution

- <2 µrad Deviation after Temperature Cycling (See the Test Data Tab for Details)

The Polaris Kinematic Platform Mount provides a flat mounting surface with high-resolution angular adjustment. The mounting surface features an array of nine 8-32 (M4) tapped holes and one #8 (M4) clearance hole for mounting threaded components. The clearance hole and two of the tapped holes each include two alignment pin holes, which allow the user to precisely align components mounted on these holes using dowel pins. Standard Ø2 mm DIN 7-m6 ground dowel pins are recommended.

The POLARIS-K1M4(/M) includes two removable Ø0.60" adjuster knobs. The adjusters can be driven by a 5/64" (2 mm) hex key or the HKTS-5/64 hex key thumbscrew (sold below), and can be locked using our POLARIS-LN1 lock nut or POLARIS-LNS1 locking collar (also sold below); see the image to the right for examples of adjustment methods. For applications that require frequent tuning of the adjusters, the lock nut or locking collar only needs to be lightly tightened to a torque of approximately 4 to 8 oz-in (0.03 to 0.06 N·m). For long term stability, we recommend tightening to a torque of 32 oz-in, which can be achieved by using our TW13 preset torque wrench (sold below).

The platform mount can be mounted horizontally on a post using the #8 (M4) counterbore on the back plate of the mount. A clearance hole is provided on the top of the mount for a #8 (M4) cap screw. The platform mount can also be oriented vertically on a post using either of the two #8 (M4) counterbores on the sides of the back plate. Each of these holes for post-mounting includes two alignment pin holes for precise alignment in the larger optical assembly. Standard Ø2 mm DIN 7-m6 ground dowel pins are recommended. We recommend using this mount with a stainless steel post, such as our Ø1" Posts for Polaris Mirror Mounts.

Click to Enlarge

1" Cube Beamsplitter Mounted on a Polaris Kinematic Platform Mount with a Stainless Steel Clamping Arm

Click for Details

PM5 Mechanical Drawing

- Provides Clamping Force for Our Platform Mounts

- 8-32 (M4) Threads on Top and Bottom of Post

- Holds Optics up to 1.65" (41.8 mm) Tall

- Made from Heat-Treated Stainless Steel with Low Coefficient of Thermal Expansion (CTE)

The PM5(/M) Clamping Arm is designed to hold optics on the Polaris kinematic platform mount and Thorlabs' other platform mounts. The arm has an adjustable height and uses a flexure design to secure the optic. The locking screws for both adjusting the height and securing the optic can be tightened or loosened with a 5/64" (2.0 mm) hex key. The post features an 8-32 (M4) threaded stud on the bottom and an 8-32 (M4) internal thread on the top.

The all-stainless-steel design minimizes temperature-dependent hysteresis in environments with large thermal fluctuations, ensuring stable, long-term performance. The clamping arm is chemically cleaned using the Carpenter AAA passivation method to remove sulfur, iron, and contaminants from the surface. Unlike the POLARIS-K1M4(/M) sold above, the clamping arm is not assembled in a clean environment or double vacuum bagged; the user must clean the clamping arm to remove any dust or grease from the surface if it will be used in a clean environment.

- For Convenient Adjustment of 5/64" and 2 mm Hex-Driven Actuators

- Red Anodized Adjustment Knob with Engraved Hex Size

- Replaceable Hex Tip

- Sold in Packages of 4

These 5/64" Hex Key Adjuster Thumbscrews allow for quick adjustment of many 5/64" and 2 mm hex-driven actuators (or standard actuators with the knobs removed). These temporary knobs can be left in the screw's hex socket between adjustments for convenience (see Figure 206A). An 8-32 setscrew (5/64" hex) secures the replaceable hex bit, which can be reversed if the tip is stripped. Contact Tech Support to order replacement hex key bits.

We offer hex key thumbscrews in sizes from 0.050" to 3/16" and 2 mm to 5 mm.

Click to Enlarge

Figure 408A F25USK2 Knob Shown Attached to a POLARIS-K1E Mirror Mount

- Ø0.925" Knob for Additional Angular Resolution

- Clearance Hole Allows Access to Hex Socket of the Adjuster

This removable adjustment knob is compatible with many of our 1/4"-100 adjusters, including those used in the Ø1", Ø1.5", and Ø2" Polaris Kinematic Mounts and our Polaris Kinematic Platform Mount. The larger Ø0.925" size provides additional angular resolution over the standard Polaris knobs.

Please note that the F25USK2 knob is not compatible with Polaris mounts that use side-hole adjusters. The recessed bore of knob is not deep enough to allow the knob to engage the threads on the side-hole adjuster.

Video 591A To install a lock nut without cross threading, gently place the lock nut against the end of the adjuster. "Unscrew" the nut until the threads of the nut and the adjuster align before threading the nut onto the adjuster. This animation shows the installation of a POLARIS-LN1 lock nut on a

- Provides Long Term Adjuster Stability

- Compatible with Select Polaris Mounts

- 0.08" (1.9 mm) Thick

- 13 mm Hex Can Be Tightened with Thin-Head or Cone Wrench

This lock nut is compatible with Polaris mounts that have 1/4"-100 adjusters, excluding the piezo-driven mounts, mounts with low-profile adjusters (Item #s POLARIS-K1E3, and POLARIS-K1E2), and vertically driven mounts (Item #s POLARIS-K1VS2 and POLARIS-K1VS2L). Designed for long-term adjuster stability or applications that are exposed to shock and vibration, the lock nut is pre-greased with the same ultra-high-vacuum-compatible, low-outgassing PTFE grease as the Polaris mounts and has been tested for adjuster fit.

For applications that require frequent tuning of the adjusters, the lock nuts only need to be lightly tightened by hand to a torque of approximately 4 to 8 oz-in (0.03 to 0.06 N·m). For long term stability, we recommend tightening to a torque of 32 oz-in, which can be achieved by using our TW13 preset torque wrench (sold below). POLARIS-LN1 lock nuts have a 13 mm hex. To avoid cross threading the lock nut, place it against the adjuster and "unscrew" the lock nut until you feel a slight drop; then thread the lock nut onto the adjuster.

- Provides Long-Term Adjuster Stability

- Compatible with Select Polaris Mounts

- Low Profile: Ø0.33" (Ø8.4 mm) x 0.08" (1.9 mm) Thick

- Tighten Along Rotational Axis Using the POLARIS-T2 Spanner Wrench

This locking collar is compatible with Polaris mounts that have 1/4"-100 adjusters, excluding the piezo-driven mounts and mounts with low-profile adjusters (Item #s POLARIS-K1E3 and POLARIS-K1E2). Designed for long-term adjuster stability or applications that are exposed to shock and vibration, these locking collars are pre-greased with the same ultra-high-vacuum-compatible, low-outgassing PTFE grease as the Polaris mounts and have been tested for adjuster fit.

The POLARIS-T2 spanner wrench has been specifically designed for use in securing the POLARIS-LNS1 locking collar. The double spanner head enables complete engagement while the design allows locking collar adjustments to be along the same line as the adjuster itself. A center through hole allows a 2 mm ball driver to pass through the spanner wrench, so that the adjuster can be held in position while the locking collar is engaged.

For applications that require frequent tuning of the adjusters, the locking collar only needs to be lightly tightened to a torque of approximately 4 to 8 oz-in (0.03 to 0.06 N·m). For long-term stability, we recommend tightening to a torque of 32 oz-in, which can be achieved by using our TW13 preset torque wrench (sold below) in combination with the POLARIS-T2 spanner wrench. To avoid cross threading the locking collar, place it against the adjuster and "unscrew" the collar until you feel a slight drop; then thread the collar onto the adjuster.

Click for Details

Figure 677B TW13 Torque Wrench Used to Secure POLARIS-LN1 Lock Nut on POLARIS-K2S2 Mirror Mount

Click to Enlarge

Figure 677A The TW13 wrench is engraved with its preset torque value and item #.

- 13 mm Hex for Use with POLARIS-LN1 Lock Nut and POLARIS-T2 Spanner Wrench, as well as POLARIS-LN4 Lock Nut

- Preset Torque Value of 32 oz-in (0.23 N•m)

- Break-Over Design Ensures Proper Torque is Applied

- Ideal for Applications Requiring Long-Term Locking

This torque wrench has a preset torque value of 32 oz-in for use with the

POLARIS-LN1 lock nut used on Polaris® mounts as well as the POLARIS-T2 spanner wrench. The wrench is also compatible with the POLARIS-LN4 lock nut. When the preset torque value has been achieved, the break-over design will cause the pivoting joint to "break," as shown in Figure 677B. The wrench's hex head will move back into place once the force is removed. This design prevents further force from being applied to the lock nut. Engraved guidelines indicate the angle the wrench should pivot in order to apply the specified torque; pivoting the handle past these guidelines will over-torque the lock nut. The wrench is also engraved with its preset torque value, torque direction, wrench size, and item # for easy identification in the field.

This wrench is designed to be compatible with cleanroom and vacuum chamber applications. It is chemically cleaned using the Carpenter AAA passivation method to remove sulfur, iron, and contaminants from the surface. After passivation, it is assembled in a clean environment and double vacuum bagged to eliminate contamination when transported into a cleanroom. The wrench has a bead blasted finish to minimize reflections when working with setups that include lasers.

Please note that these wrenches are not intended for use in applications where adjusters are frequently tuned, as these applications typically require torque values of 4 to 8 oz-in (0.03 to 0.06 N·m).

Products Home

Products Home

Zoom

Zoom

Polaris® Kinematic Platform Mount

Polaris® Kinematic Platform Mount