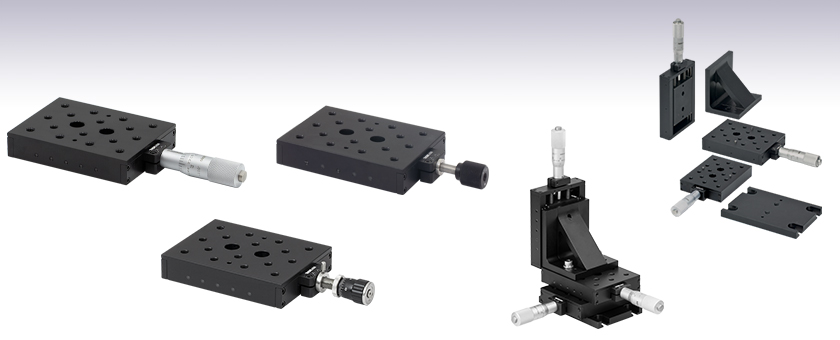

1" (25 mm) Travel Translation Stages

- 3" x 4" Stage with 1/4"-20 or M6 Mounting Holes

- Modular Design for 1-, 2-, or 3-Axis Stages

- Models with Adjuster Screws, Micrometers, or Differential Adjusters

Standard

Micrometer

PT1

PT1B

Adjuster

Screw

PT1A

Differential

Adjuster

PT3

XYZ Translation Stage

PT1

PT102

PT101

Components of PT3

Please Wait

| Common Specifications | |

|---|---|

| Travel | 1.00" or 25.0 mm (Model Dependent) |

| Configuration | Left- or Right-Handed |

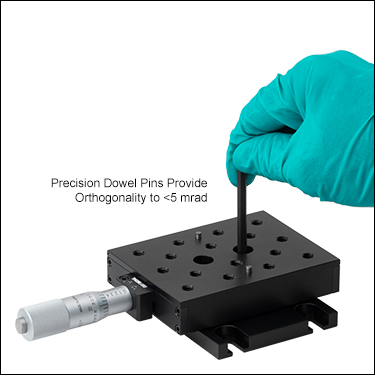

| XY Stacked Orthogonality | <5 mrad |

| Angular Deviation | <250 µrad |

| Bearing Type | Ball on Hardened V-Grooves |

| Ball Bearing-Mechanism Manual Translation Stages |

|---|

| 1/4" (6 mm) Travel |

| 1/2" (13 mm) Travel |

| 1/2" (13 mm) Travel, Miniature |

| 1" (25 mm) Travel |

| 2" (50 mm) Travel |

Features

- Modular Design Allows Stages to be Easily Configured in XY and XYZ Orientations

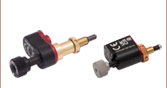

- Versions Available with Adjuster Screw, Micrometer, or Differential Adjuster

- Wide Range of Compatible Actuators (See Actuators Tab for Details)

- Sixteen 1/4"-20 (M6) Tapped Mounting Holes

- Right-Angle Bracket for XZ or XYZ Configurations

- Base Plate for Breadboard or Optical Table Mounting

Thorlabs' PT Translation Stages have a 1.00" (25.0 mm) translation range and feature hardened steel linear bearings for precise motion and long life. These translation stages are available preconfigured with an adjuster screw, standard manual micrometer, or differential adjuster. The actuator on the translation stage can be removed by loosening the screw on the barrel clamp with a 3/32" (2.5 mm) hex key.

Each stage comes with two precision dowel pins that allow the PT series of translation stages to be stacked in right- or left-handed XY configurations with excellent orthogonality of <5 mrad. The right-handed XYZ configuration, with either the standard manual micrometer or the differential micrometer, is available fully assembled below.

Custom Options

Any PT series translation stage can be purchased as a special order without a micrometer, thereby allowing the user to choose from our large selection of manual and motorized actuators. We also offer screw adjusters that have Ø3/8" barrel adapters for 1/4"-80, 1/4"-100, or M6 x 0.25 threads, making them compatible with the stages below. Please see the selection guide in the Actuators tab for a list of compatible actuators. Please contact Tech Support to discuss the various micrometer options and to get quotes for custom configurations with or without alternative actuator options.

PT101(/M) Base Plate

The PT101(/M) Base Plate is ideal for XY or XYZ multi-axis configurations where the standard counterbores in the middle of the stages are obstructed. It has 1/4" (M6) counterbore slots for mounting to a breadboard or optical table and comes with the two 1/4"-20 (M6) cap screws that are needed to attach it to a PT series stage.

PT102(/M) Angle Bracket

The PT102(/M) Angle Bracket allows for a PT series stage to be oriented vertically, making left- or right-handed XYZ, XZ, and XY configurations possible. For information on constructing an XYZ configuration from individual components, see the XYZ Assembly tab.

Click to Enlarge

Figure 2.2 PT101 Base Plate used to create clearance for mounting a DM713 Digital Micrometer to a PT1 Stage.

Any of the translation stages featured here can be purchased as a special order without an actuator, thereby allowing the user to choose from our large selection of manual and motorized actuators. We also offer screw adjusters that have Ø3/8" barrel adapters for 1/4"-80, 1/4"-100, or M6 x 0.25 threads, making them compatible with the stages in Table 2.1. When choosing a custom actuator, please be aware of the barrel size of the actuator. Please contact Tech Support to discuss the various micrometer options and to get quotes for custom configurations with or without alternative actuator options.

| Table 2.1 Actuator Compatibility | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | Barrel Diameter |

Description | PT1B | PT1B/M | PT1 | PT1/M | PT1A | PT1A/M |

| F25ES100 | 3/8" | 1/4"-170 Matched Adjuster/Bushing Pair |  |

|

|

|

|

|

| 150-811ST | 1" Travel Micrometer |  |

|

|

|

|

|

|

| 150-801STa | 10 mm | 25 mm Travel Micrometer | - | - | - | - | - | - |

| 150-801ME | 3/8" | 25 mm Travel Micrometer |  |

|

|

|

|

|

| 146-200 | High-Precision Micrometer |  |

|

|

|

|

|

|

| DM12b | 1" Travel Differential Adjuster |  |

|

|

|

|

|

|

| DM713c | 1" Travel Digital Micrometer |  |

|

|

|

|

|

|

| ZST225B | 25 mm Travel Stepper Actuator |  |

|

|

|

|

|

|

| Z925B | 25 mm Travel Motorized Actuator |  |

|

|

|

|

|

|

| ZFS25B | 25 mm Travel, Compact Stepper Motorized Actuator |  |

|

|

|

|

|

|

| Z925BV | 25 mm Travel, Vacuum-Compatible, Motorized Actuator |  |

|

|

|

|

|

|

The actuators above are compatible with all of the stages offered on this page, with the exception of PT1/M and PT3/M stages sold before December 30, 2015. Please refer to the footnotes above for more information.

XYZ Assembly

The modular design of the PT series translation stages allows the assembly of 2- or 3-axis stages within minutes. Each stage comes with two precision dowel pins that allow for right- or left-handed XY configurations with excellent orthogonality. Follow the steps in Video 3.1 or Figures 3.2, 3.3, 3.4, and 3.5 to build a 3-axis XYZ translator (PT3) from individual components.

Step One

Figure 3.2 Insert the two 1/8" alignment pins into the PT101(/M) Base and then screw it onto a PT series translation stage using the two included 1/4"-20 (M6) cap screws. Then insert the two 1/8" alignment pins into the provided holes to ensure orthogonality of the second stage.

Step Two

Figure 3.3 Attach the second, orthogonal PT series translation stage, as shown above, using two 1/4"-20 (M6) cap screws. Then insert the two 1/8" alignment pins into the provided holes for aligning the angle bracket.

Step Three

Figure 3.4 Screw the PT102(/M) Angle Bracket to the PT series translation stage, as shown above, using two 1/4"-20 (M6) cap screws. Then insert the two 1/8" alignment pins into the provided holes on the front face of the angle brakcet for aligning the third and final stage.

Step Four

Figure 3.5 Screw the third PT series translation stage to front of the PT102(/M) Angle Bracket, using two 1/4"-20 (M6) cap screws.

Click to Enlarge

Figure 4.1 PT1 Packaging

| Item # | % Weight Reduction |

CO2-Equivalent Reductiona |

|---|---|---|

| PT1 | 27.48% | 74.38 kg |

Smart Pack

- Reduce Weight of Packaging Materials

- Increase Usage of Recyclable Packing Materials

- Improve Packing Integrity

- Decrease Shipping Costs

Thorlabs' Smart Pack Initiative is aimed at waste minimization while still maintaining adequate protection for our products. By eliminating any unnecessary packaging, implementing packaging design changes, and utilizing eco-friendly packaging materials for our customers when possible, this initiative seeks to improve the environmental impact of our product packaging. The PT1 is now shipped in re-engineered packaging that minimizes the weight and the use of non-recyclable materials. b

Insights into Motion Control Using the DM713 Digital Micrometer

Scroll down to read about:

- Recording Position from Digital Micrometers

- DM713 Digital Micrometer: LabVIEW and C# Programming References

Click here for more insights into lab practices and equipment.

Recording Position from Digital Micrometers

Click to Enlarge

Figure 186B The SBC-COMM package shown here can be used to log data position data displayed by the DM713 digital micrometer.

Click to Enlarge

Figure 186A The DM713 digital micrometer (right) is included with and used to adjust the retardance provided by the

Digital micrometers, such as the DM713, are handy for moving a piece of optomech a specific distance. For example, a user might want to increment a translation stage holding a sample in front of an objective lens in order to focus the light to equally spaced points within the sample.

However, there are also times where the user might want to record the position of an event. One example could be making a distance measurement where the micrometer is set to a starting position, zeroed, and then translated the desired amount to display the distance.

Using the DM713 alone creates an extra step where the user has to read and record the display, which can be tedious in a dark lab where the display is not visible. One solution is to use Thorlabs' SBC-COMM, which includes an RS-232 interfacing cable. Thorlabs has created software application notes that walk the user through creating Visual C#® and LabVIEW® programs to continuously measure distances with the DM713. The application notes can be downloaded from links in the following section.

Another solution is to purchase the Mitutoyo® 05CZA662 SPC cable and IT-016U USB input tool that provide a push button and USB interfacing cable. With this device the user can open any text entry software package, press the single push button, and the device acts like a keyboard to enter the number into the software.

Date of Last Edit: Dec. 4, 2019

DM713 Digital Micrometer: LabVIEW and C# Programming References

Click to Enlarge

Figure 186C Visual C# and LabVIEW programs can be written to interrogate the DM713 Digital Micrometer. Examples are detailed in programming references available for download.

Programming references that provide introductions to communicating with the DM713 Digital Micrometer (Figure 186C) are available. One reference has been developed for LabVIEW, and the other for Visual C#. Each reference includes a step-by-step discussion for writing the program, as well as a section that concisely provide the full program text without explanation.

Included in the LabVIEW Programming Reference:

- Instructions for downloading and installing the driver software.

- Information concerning the required cabling and connecting to the DM713's COM port.

- Creation of a new VI that establishes serial communications with the DM713.

- Data from the DM713 is continuously received.

- The displacement value and its units of measurement are displayed.

- Logging a data value in response to a button click is implemented.

Included in the Visual C# Programming Reference:

- Information for connecting the computer to the DM713's COM port.

- Instructions for spawning a secondary thread to continuously communicate with the DM713.

- Procedure for operating on the received data, to extract the displacement value and units.

- Instructions for displaying the displacement values and units in the program's GUI.

- Logging a displacement value to a file in response to a button click.

Date of Last Edit: Dec. 4, 2019

| Posted Comments: | |

Pau Iba

(posted 2025-10-15 07:29:40.81) The step file is missing and I would appreciate getting access to it.

Thanks jdelia

(posted 2025-10-17 09:56:24.0) Thank you for contacting Thorlabs. The STEP file can be downloaded directly from the website by clicking on the red "Documents" icon next to the part number. Yuan Gao

(posted 2025-07-16 17:01:54.553) Hi, I’d like to confirm the load capacity of the PT1 stage. The specifications list 8.8 lb vertical and 90 lb horizontal capacities. My understanding is that “vertical” refers to the direction along the steel linear bearings, while “horizontal” refers to the direction perpendicular to them. Based on this, I assume the stage can also be mounted upside-down to suspend a load from above, like from a ceiling.

Could you please confirm whether this assumption is correct? ksosnowski

(posted 2025-07-17 02:35:42.0) Hello Yuan, Thanks for reaching out to us. While our horizontal testing has only been with PT1 sitting flat on a surface, the bearings in the stage will see the same contact points if this is hanging upside down and so this orientation should have similar performance. The Solidworks file we post for this stage includes the internal bearing features. I have reached out directly to discuss this application further. David Rigolo

(posted 2025-07-02 15:06:53.97) Do you provide a kit or a service to rebuild PT1? I have 3 on my desk that are quite loose. jdelia

(posted 2025-07-03 01:57:50.0) Thank you for contacting Thorlabs. We do not provide a service kit for our stages, but we are happy to help troubleshoot if the device is out of spec or not functioning properly and take it in for inspection and/or repair if necessary. I have reached out to you directly to clarify the issue with your PT1 units and begin the troubleshooting process. Thomas Auzinger

(posted 2024-11-07 11:17:49.243) There is a discrepancy between the different metric product documents:

The Auto CAD PDF document claims that the dimensions listed in mm are exact and the one in inch rounded. However, the Solidworks file of the product dimensions that exactly fit the inch measurement.

For example in the Auto CAD PDF, the P101/M product has a height of exactly 9.1mm and a corresponding rounded measurement of [0.36in]. The Solidworks model of this product has, however, a height of 9.144mm, which is exactly 0.36in.

I observed the same issues with other models as well. Why is there such a discrepancy?

Which of these documents can be considered the source of truth? cdolbashian

(posted 2024-11-14 01:41:17.0) Thank you for reaching out to us with this observation. Our mechanical drawings presented will often round a decimal place for brevity, as these are not official machine drawings. If you are in need of more specific dimensions, we are happy to share them directly via email. I have contacted you directly, in this instance, to share more specific dimensions regarding the PM101 and PM101/M. SJ Kim

(posted 2024-07-17 16:23:27.647) I have got the confusion with the PT3/M's frontside, bolt and dowel pin attaching insert section.

I am preparing a counter parts for this PT3/M stage module.

At the front side,

much of M6 thread holes and 2 of dowel pin attaching positions are exist.

And among the repeating of the bolt and dowel pin insert holes,

instead of normal undertstanding (commonly it would be understood as the distance between is 12.5mm, as the PDF format part drawing description)

but there have some of measured part as 12.49mm in the 3D modeling STP data,

Can you tell me which of exact distance value is correct?

Actually, 0.01mm deviation, can be easily passed over,

but considering the tolerance stack of the counter part's attaching positional vary, I think it should be exactly kept.

Thank you and best regard.

if there needs any reference image or any data please let me know

i will feedback through the mail. (sjkim@korthern.co.kr) jdelia

(posted 2024-07-18 09:07:04.0) Thank you for contacting Thorlabs. The spacing you are referencing has a nominal value of 0.492" (12.4968 mm). Stuart MacFarquhar

(posted 2023-03-15 16:04:49.877) Please could you review the AutoCAD PDF technical drawing, specifically the spacing of the tapped M6 holes? These are listed as separated by 25.4 mm, however a custom part ordered to fit these does not fit, and measurement of the PT1/M plate suggests the spacings are in fact 25.0 mm. jdelia

(posted 2023-03-24 10:01:04.0) Thank you for contacting Thorlabs. The M6 tapped holes on the PT1/M are in fact spaced 25 mm apart. The 25.4 mm measurement you mentioned just refers to the two center counterbored holes. I have reached out to you directly to clarify this further. Philipp Treutlein

(posted 2023-02-21 14:08:29.243) Can I order the 1/8 alignment pins separately? jdelia

(posted 2023-02-22 10:09:19.0) Thank you for contacting Thorlabs. We are reaching out to you directly regarding a quote for these component dowel pins. tom.dzelzainis

(posted 2019-03-12 10:53:27.517) Hi,

Is it possible to get the PT3 with imperial tapped holes, but a metric micrometer.

Thanks,

Tom. llamb

(posted 2019-03-12 03:41:47.0) Yes. You may manually swap the 150-801ME metric micrometers into the PT3 after removing the imperial 150-811ST micrometers. Otherwise, you may contact techsupport@thorlabs.com for requests on custom pre-configured products. We have reached out to you by email to quote this particular custom product. mark_bowen

(posted 2017-12-12 17:03:32.893) We have used hundreds of PT1 stages in the past. They proved to lack sufficient stiffness for my recent application, so I considered the DTS25 as an option. The website provides stiffness specs for the DTS, but the specs for the ball and roller slides do not. That would be a helpful characteristic to list so the products can be compared. tfrisch

(posted 2017-12-15 09:51:06.0) Hello, thank you for contacting Thorlabs. PT1 has its micrometer attached to the moving carriage rather than the baseplate, so likely the effect you are seeing is due to the weight or torque of your hand moving the stage. I will pass on your note about product comparison characteristics to our Engineering Team. clare.dillon

(posted 2016-07-25 09:55:33.307) I wondered if you could tell me what the repeatability of the PT1/M micrometer is please, and what the hysteresis is in the mechanism? Thanks. cpepe

(posted 2016-06-07 15:11:55.133) Hi, I was wondering if you could tell what material the "XYZ Translation Stage with Standard Micrometers PT3/M" is made of? besembeson

(posted 2016-06-08 09:42:26.0) Response from Bweh at Thorlabs USA: It is mostly anodized aluminum (for the main body) and hardened alloy and stainless steel for other sub components. tomerg

(posted 2015-11-04 09:03:15.663) Hello, I want to inquire regarding the PT1A/M: the distance between the CBORE for M6 is 25.4mm while for most of the metric products the mounting holes distance is 25mm. Is it Ok? is there enough freedom to assemble the PT1A/M on metric items (specifically, AP30/M)?

Thanks, Tomer. jlow

(posted 2015-11-04 11:57:47.0) Response from Jeremy at Thorlabs: The counterbored holes on the metric PT1-series stages are oversized so they can be used on 25mm hole pattern. t.isaac

(posted 2015-05-05 10:51:24.09) Please could you tell me the maximum cantilevered load (axial and transverse) of the PT1A/M stage? cdaly

(posted 2015-05-18 08:50:40.0) Response from Chris at Thorlabs: At the moment, we do not have measured limits for the permissible torque on the PT1 series of stages, but we will contact you directly in order to discuss your application and how appropriate this stage if for you. khaded

(posted 2014-12-05 10:31:14.7) How can I order the PT3 stage with the bottom stage rotated 180 deg. (because of interference of the micrometer with another component).

Thanks,

Kevin Haded cdaly

(posted 2014-12-05 05:49:18.0) Response from Chris: To order a left handed version, or any other custom, you can request this from us at techsupport@thorlabs.com. I will contact you directly about this, but it should be noted that the stage can easily be disassembled and reoriented using just a 3/16" hex key. fitilis

(posted 2014-03-27 10:58:29.427) Is there a lock screw on the stage to prevent movement of the stage when the position is set? cdaly

(posted 2014-03-27 04:25:11.0) Response from Chris at Thorlabs: The PT1 series of stages do not have a locking mechanism. The 1/2" travel MT1 and 1" travel LNR25M do have a locking mechanism though. davoodahadpour

(posted 2013-10-28 04:14:19.637) XYZ Translation Stage with Standard Micrometers tcohen

(posted 2013-10-29 13:12:00.0) Response from Tim at Thorlabs: We’ll contact you directly to discuss any questions you might have on the PT3. user

(posted 2013-10-03 14:19:41.457) Hello,

I am planning to use a PT1B/M mounted vertically. Do you offer any locking rings for the ¼”-170 adjustment screw of the stage, if not is there another adjustment screw with locking rings compatible with the stage?, an adjustment screw with a coarser pitch will not be a problem for my application. Thank for your time.

TA tcohen

(posted 2013-10-03 12:46:00.0) Response from Tim at Thorlabs: Thank you for contacting us. We do sell locking rings separately for other adjustment screws which could be fitted (http://www.thorlabs.com/navigation.cfm?guide_id=131). For this TPI, although these aren’t in our catalog yet, we can likely offer them as a special. I see you haven’t left us any contact information, so if you would like to discuss this further and receive a quote, please contact us at techsupport@thorlabs.com. tcohen

(posted 2012-10-19 18:18:00.0) Response from Tim at Thorlabs: To avoid obstructing the path during translation underneath the mounting body, the screws should not exceed the length of the tap, which is just over 5.8mm. dnelson

(posted 2012-10-19 12:46:20.46) What's the maximum lnegth of 1/4-20 screws that can be used with the PT1? Buki at Thorlabs

(posted 2011-01-26 14:10:20.0) We have tested the PT1/M in a similar setup by mounting a P4 (4” long post), a PT3 and then two MB12s (6kg total) onto the P4 post. In this arrangement, the vertical stage still moves smoothly so you should not experience any degradation in performance. Please contact TechSupport@thorlabs.com if you want to further discuss your application. remco.de.vries

(posted 2011-01-24 01:42:34.0) Dear sir,

I want to use the PT1/M for a construction. Therfore we have to munt a approc. 6kg heavy chamber a 10 cm of the stage. The stage itself can bear 9kg, but Im interesting in the pitch moment of the stage. Is this possible with this stage?

with kind regards,

Remco de Vries Thorlabs

(posted 2010-06-29 11:01:34.0) Response from Javier at Thorlabs to martin.kahle: The PT102 is not compatible with the DT25 stages; the mounting holes do not match. However, the AP90 right angle bracket is compatible with these dovetail stages (http://www.thorlabs.de/NewGroupPage9.cfm?ObjectGroup_ID=224&pn=AP90). I will send you an assembly example consiting of two DT25 stages and one AP90. martin.kahle

(posted 2010-06-29 11:22:35.0) Is the PT102 cmapatible with the dovetail translation stages like DT25? Thorlabs

(posted 2010-06-24 10:26:54.0) Response from Javier at Thorlabs to last poster: you do not need to buy additional components in order to complete the assembly of the PT3A/M. The actuators, right angle bracket, and mounting base are all included. user

(posted 2010-06-24 09:06:49.0) Dear Sir

Do I need any other accessories like actuators, base plates for PT3A/M jjurado

(posted 2010-06-01 14:59:35.0) Response from Javier at Thorlabs to michael.roth: The PT101 is compatible with both imperial and metric versions of the PT1. The slotted mounting holes provide enough clearance so that you can attach the base onto a breadboard/optical table with 50.0 mm hole spacing. michael.roth

(posted 2010-06-01 11:04:33.0) Hello,

i need to mount a PT1/M Translation Stage on a breadboard with 50.0mm hole spacing. What would you recommend since the PT101 has a 51mm hole spacing? Can you use the PT101 also with 50mm hole spacings?

Thank you for your answer. Adam

(posted 2010-03-19 09:19:46.0) A response from Adam at Thorlabs to Bowen: The distance from the bottom of the stage shown in detail A to the table top is 35.67mm when the stage is midway in travel. I will email you directly to see if any more dimensiosn are needed. bowen

(posted 2010-03-19 08:37:47.0) For the drawing of PT3, what users would like to know is the height of detail A above the tabletop (where the stage would rest). This value does not seem to be in the drawing. Youd really like to know it when the micrometer is in the midrange, not at one end of the travel. jens

(posted 2009-06-12 18:04:51.0) A reply from Jens at Thorlabs: I am sorry for the inconvenience. I will send you the file via email and have our web team fix the link. smithm1

(posted 2009-06-12 16:12:31.0) I need a solidworks model of this part. Youre downloads are not working. Can you e-mail me one or get the system working?

Thank you.

~Mark technicalmarketing

(posted 2007-12-12 12:02:06.0) Dear jschumacher,

Thank you for brining our attention to the PT3 image. The picture was not accurate and has been replaced. The block is not part of the PT3 (Please see the updated image). jschumacher

(posted 2007-11-13 05:20:31.0) if I click on PT3 a picture is shown that includes a block between the second and third stage. This block would be very helpful. Which item number is it? acable

(posted 2007-08-20 13:25:06.0) It would also be nice to use the same sort on the price box for the metric products as is used for the imperial products. Also even if the PT101 is truely universal i would list it in both price boxes, it is arkward to need to go into two places to put together a system. europe

(posted 2007-08-20 10:43:38.0) please take a look on the web page for PT101 :

there is no hint for customers that the PT101 is universal ( if so why does it have 1/4-20 tap???) and fits with the /M parts - can you advice with the web team that they do a comment?

Thanks |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The XP and LNR Series stages feature all stainless steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see Table 140E).

| Table 140A Crossed-Roller Bearing Stages | |||||||

|---|---|---|---|---|---|---|---|

| Product Family | XP Series 10 mm Stages |

LNR Series 25 mm Stages |

LX Series 25 mm Stages |

XRN Series 25 mm Stages |

XR Series 25 mm Stages |

XR Series 50 mm Stages |

LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

| Travel | 10 mm (0.39") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Thumbscrew | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) |

2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | |||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Table 140B Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Table 140C Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Table 140D Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Table 140E Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage |

XR Series 14 mm Vertical Stage |

MVS Series 1/2" Vertical Stage |

MVS Series 1" Vertical Stage |

VAP Series 4" Vertical Stage |

VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

| Item # | PT1B | PT1B/M |

|---|---|---|

| Actuator | 1/4"-170 TPI Adjustera | |

| Resolution | 0.006" (149.4 µm) Translation per Revolution |

|

| Travel | 1.00" (25.4 mm) | |

| Taps | 1/4"-20 (Qty. 16) | M6 (Qty. 16) |

| Barrel Size | Ø3/8" (Ø9.5 mm) | |

| Vertical Load Capacity (Max) | 7 lbs (3.2 kg) | |

| Horizontal Load Capacity (Max) | 7 lbs (3.2 kg) | |

The PT1B(/M) translation stage is configured with a 1/4"-170 TPI adjuster, which has a 1.00" (25.4 mm) travel range. The adjuster can either be actuated by hand or by the 5/64" (2.0 mm) hex located on the end. Each stage includes two alignment dowel pins and contains sixteen 1/4"-20 (M6) tapped mounting holes that are 0.22" (5.8 mm) deep. Two oversized 1/4" (M6) counterbores allow the stage to be directly attached to a mounting adapter (sold below) or a metric or imperial breadboard with user-supplied cap screws.

| Item # | PT1 | PT1/M |

|---|---|---|

| Actuator | 150-811ST Micrometer | 150-801ME Micrometer |

| Resolution | 0.025" Translation per Revolution |

0.5 mm Translation per Revolution |

| Travel | 1.00" | 25.0 mm |

| Engraving | 0.001" (25.4 µm) per Division |

10 µm (0.0004") per Division |

| Taps | 1/4"-20 (Qty. 16) | M6 (Qty. 16) |

| Barrel Size | Ø3/8" (Ø9.5 mm)a | |

| Vertical Load Capacity (Max) | 8.8 lbs (4.0 kg) | |

| Horizontal Load Capacity (Max) | 90 lbs (41 kg) | |

The PT1(/M) translation stage is configured with the 150-811ST micrometer drive, which has a 1.00" travel range and engraved graduations every 0.001". The PT1/M is fitted with the metric 150-801ME micrometer, which has a 25.0 mm travel range and engraved graduations every 10 µm. Each stage includes two alignment dowel pins and contains sixteen 1/4"-20 (M6) tapped mounting holes that are 0.22" (5.8 mm) deep. Two oversized 1/4" (M6) counterbores allow the stage to be directly attached to a mounting adapter (sold below) or a metric or imperial breadboard with user-supplied cap screws.

| Item # | PT1A | PT1A/M |

|---|---|---|

| Actuator | DM12 Differential Adjuster | |

| Coarse Resolution | 0.5 mm (0.02") Translation per Revolution | |

| Coarse Range | 1.00" (25.4 mm) | |

| Fine Resolution | 25 µm (0.001") Translation per Revolution | |

| Fine Range | 250 µm (0.01") | |

| Travel | 1.00" (25.4 mm) | |

| Engraving | 0.5 µm per Division | |

| Taps | 1/4"-20 (Qty. 16) | M6 (Qty. 16) |

| Barrel Size | Ø3/8" (Ø9.5 mm) | |

| Vertical Load Capacity (Max) | 8.8 lbs (4.0 kg) | |

| Horizontal Load Capacity (Max) | 90 lbs (41 kg) | |

For applications that require increased resolution, the PT1A(/M) translation stage is configured with the DM12 differential adjuster. The coarse adjustment, which can be locked using a thumbscrew on the mounting collar, provides 0.5 mm of translation per revolution over a range of 1.00" (25.4 mm).

The differential adjustment knob provides 25 µm of translation per revolution over a 250 µm range and features graduations every 0.5 µm. Two oversized 1/4" (M6) counterbores allow the stage to be directly attached to a mounting adapter (sold below) or a metric or imperial breadboard with user-supplied cap screws. Each stage includes two alignment dowel pins and contains sixteen 1/4"-20 (M6) tapped mounting holes that are 0.22" (5.8 mm) deep.

If the fine adjustment knob on the DM12 is accidentally removed, it can be reattached. Please refer to the DM12 Knob Attachment tab on our DM12 differential drive page for details.

| Item # | PT3 | PT3/M |

|---|---|---|

| Actuators | 150-811ST Micrometer | 150-801ME Micrometer |

| Resolution | 0.025" Translation per Revolution |

0.5 mm Translation per Revolution |

| Travel | 1.00" | 25.0 mm |

| Engraving | 0.001" (25.4 µm) per Division |

10 µm (0.0004") per Division |

| Taps | 1/4"-20 (Qty. 16) | M6 (Qty. 16) |

| Barrel Size | Ø3/8" (Ø9.5 mm)a | |

| Vertical Load Capacity (Max) | 8.8 lbs (4.0 kg) | |

| Horizontal Load Capacity (Max) | 90 lbs (41 kg) | |

- Preconfigured, 3-Axis, Right-Handed XYZ Translators

- Fully Assembled Stages Include both the PT101(/M) and PT102(/M) Adapters Plates

The PT3(/M) translation stage is fitted with standard 1" 150-811ST micrometer drives, each of which is engraved every 0.001", while its metric counterpart (PT3/M) comes with 150-801ME micrometers, which offer 25 mm of travel and are engraved every 10 µm. Each stage offers sixteen 1/4"-20 (M6) tapped mounting holes that are 0.22" (5.8 mm) deep.

The PT Series of translation stages can be purchased individually (PT1 Series above) or as fully assembled, 3-axis, XYZ translators (PT3 Series). Therefore, the PT3 stage can be disassembled using a 3/16" (5 mm) hex key to customize the positions of the micrometers or to use three PT1 stages separately, see the XYZ Assembly tab for details.

Please contact technical support if your application would benefit from a stage that is equipped with imperial taps and metric micrometer drives or vice versa.

| Item # | PT3A | PT3A/M |

|---|---|---|

| Actuators | DM12 Differential Adjuster | |

| Coarse Resolution | 0.5 mm (0.02") Translation per Revolution | |

| Coarse Range | 1.00" (25.4 mm) | |

| Fine Resolution | 25 µm (0.001") Translation per Revolution | |

| Fine Range | 250 µm (0.01") | |

| Travel | 1.00" (25.4 mm) | |

| Engraving | 0.5 µm per Division | |

| Taps | 1/4"-20 (Qty. 16) | M6 (Qty. 16) |

| Barrel Size | Ø3/8" (Ø9.5 mm) | |

| Vertical Load Capacity (Max) | 8.8 lbs (4.0 kg) | |

| Horizontal Load Capacity (Max) | 90 lbs (41 kg) | |

- Preconfigured, 3-Axis, Right-Handed XYZ Translators

- Fully Assembled Stages Include both the PT101(/M) and PT102(/M) Adapters Plates

The PT3A(/M) translation stage is offered with differential micrometers for applications requiring increased resolution. The coarse adjustment, which can be locked using a thumbscrew on the mounting collar, provides 0.5 mm of translation per revolution over a range of 1" (25.4 mm).

The differential adjustment provides 25 µm of translation per revolution over a 250 µm range. The dfferential adjustment knob features graduations every 0.5 µm. Two 1/4"-20 (M6) counterbores allow the stage to be directly attached to a breadboard or mounting adapter (sold below) with user-supplied cap screws. Each stage contains sixteen 1/4"-20 (M6) tapped mounting holes that are 0.22" (5.8 mm) deep.

The PT Series translation stages can be purchased individually (PT1 Series) or as fully assembled, 3-axis, XYZ translators (PT3 Series). Therefore, the PT3A stage can be disassembled using a 3/16" (5 mm) hex key to customize the positions of the micrometers or to use three PT1 stages separately, see the XYZ Assembly tab for details.

If the fine adjustment knob on the DM12 is accidentally removed, it can reattached. Please refer to our DM12 Knob Attachment tab on our DM12 differential drive page for details.

Click to Enlarge

Figure G6.1 PT101 Base Plate used to create clearance for mounting a DM713 Digital Micrometer to a PT1 Stage.

- Build XY and XYZ Configured Stages

- Base Plate for Optical Breadboard Mounting

- Angle Bracket for Vertical Mounting

The PT101(/M) and PT102(/M) are adapter plates designed for the PT Series translation stages. The PT101(/M) has four 1/4"-20 (M6) mounting slots on the side that enable obstruction-free mounting onto an optical breadboard. It is ideal for XY configurations or already assembled XYZ multi-axis configurations where the standard counterbores in the middle of the stages are obstructed. This base plate includes two alignment dowel pins and two 1/4"-20 (M6) cap screws.

The PT102(/M) is an angle bracket with four 1/4"-20 (M6) mounting holes that allows a PT Series stage to be mounted vertically. This is necessary in all XZ and XYZ configurations. The adapter plate includes four 1/4"-20 (M6) cap screws. It is also compatible with our manual and motorized MT Series translation stages that offer 1/2" (12.7 mm) of travel. This allows stages with different travel ranges to be easily connected within the same mechanical system.

The PT3(/M) XYZ configured stages include both the PT101(/M) and PT102(/M) adapters. Please see the XYZ Assembly tab for more information on using these adapters to create a multi-axis configuration.

Products Home

Products Home

Zoom

Zoom

Ball Bearing Mechanism

Ball Bearing Mechanism